Metals in Industrial Applications

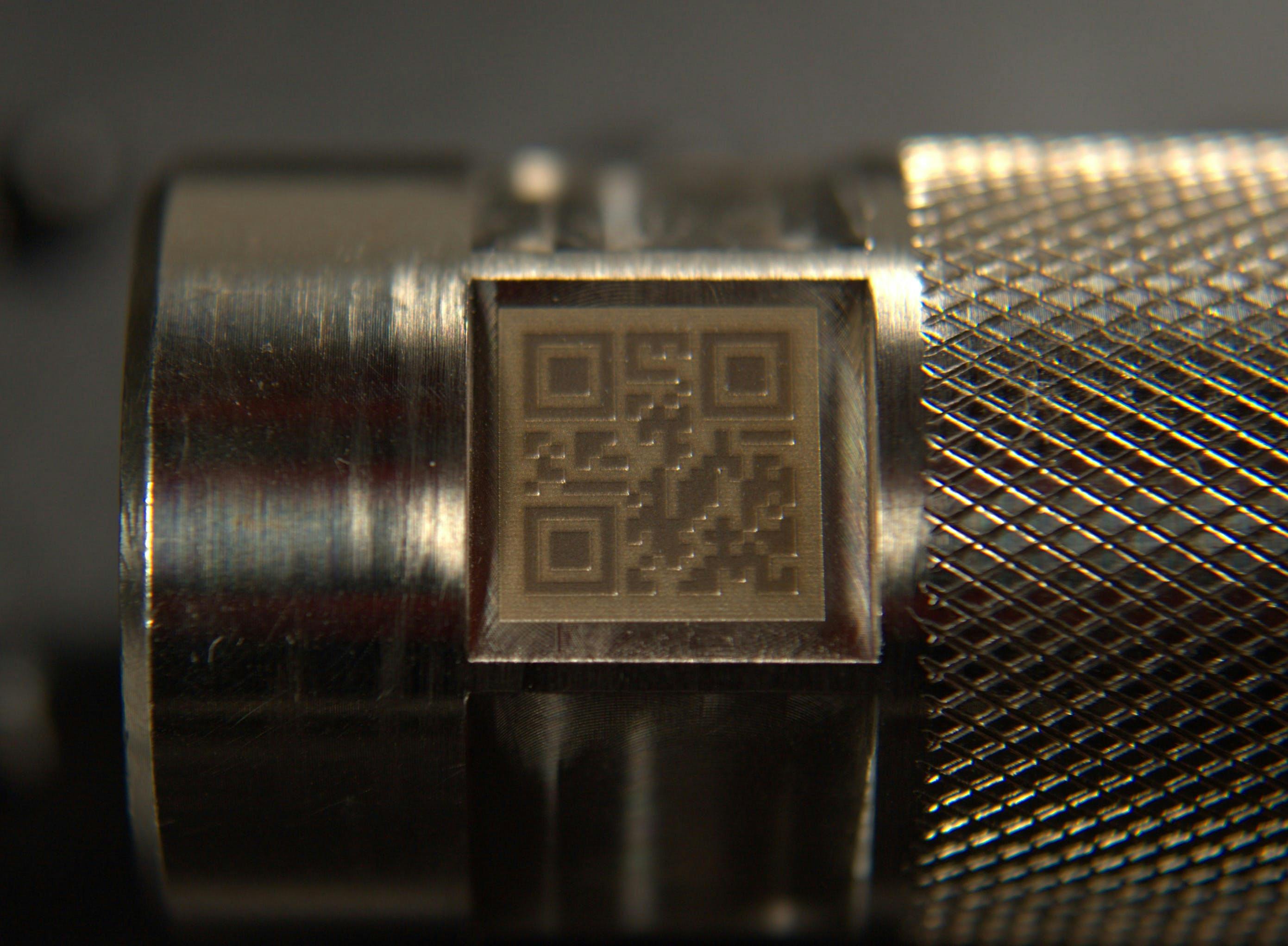

In contrast to more traditional methods of marking, the machine does not require consumables such as inks, chemicals, or pastes. The handling and disposal of these consumables will be one less thing to worry about, allowing businesses to focus on more important things. Metals that are etched using lasers do not have to undergo any pre or post-treatment. Coupled with the speed with which a laser machine works without the need for tool changes, a laser marker effectively completes the job faster and with less effort.

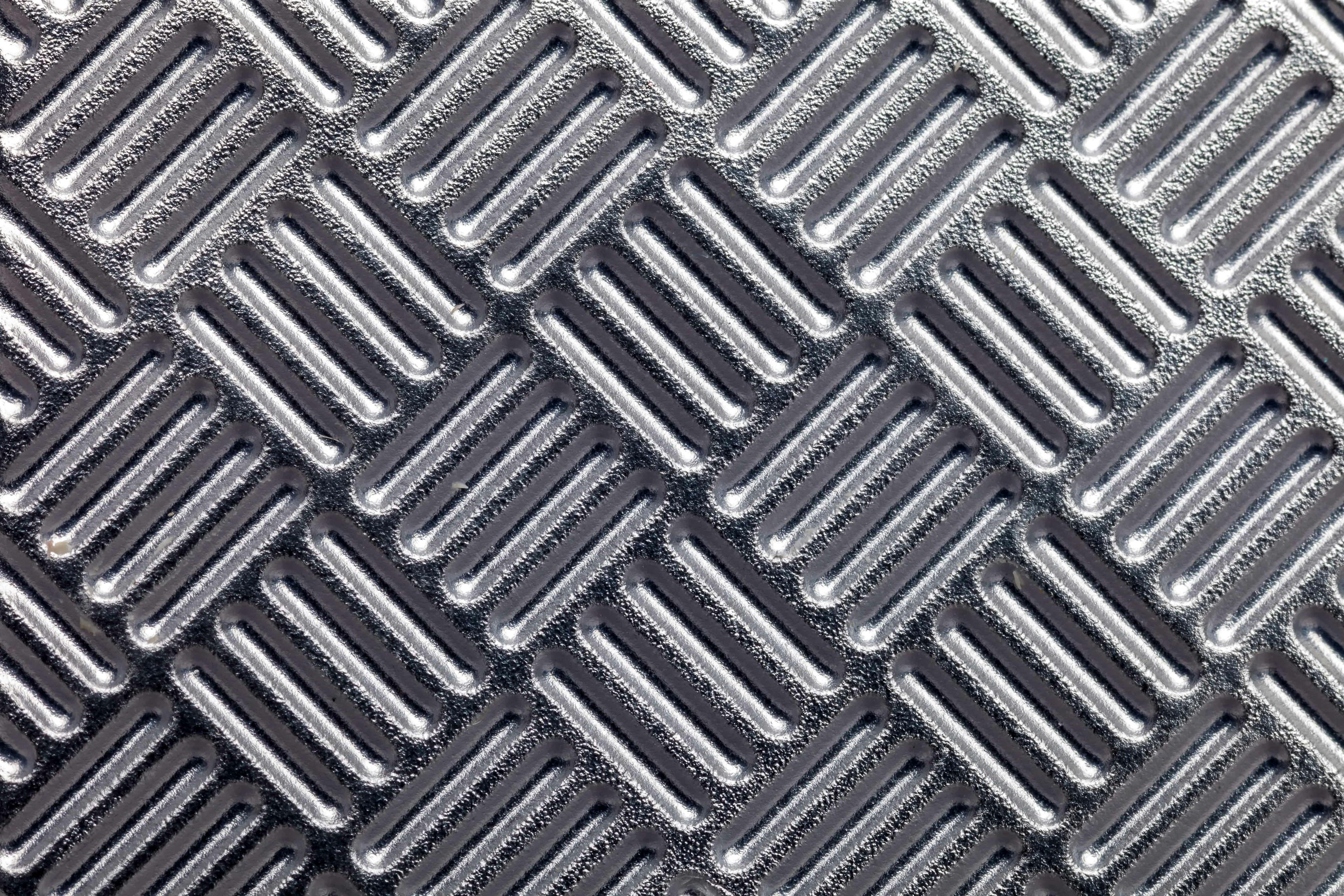

Despite the prevalence of alternative materials, there is no doubt that metals remain the workhorse of the manufacturing industry. Metals provide a unique combination of durability, workability, heat and chemical resistance, and visual appeal that makes them the material for choice for several industrial and commercial applications.

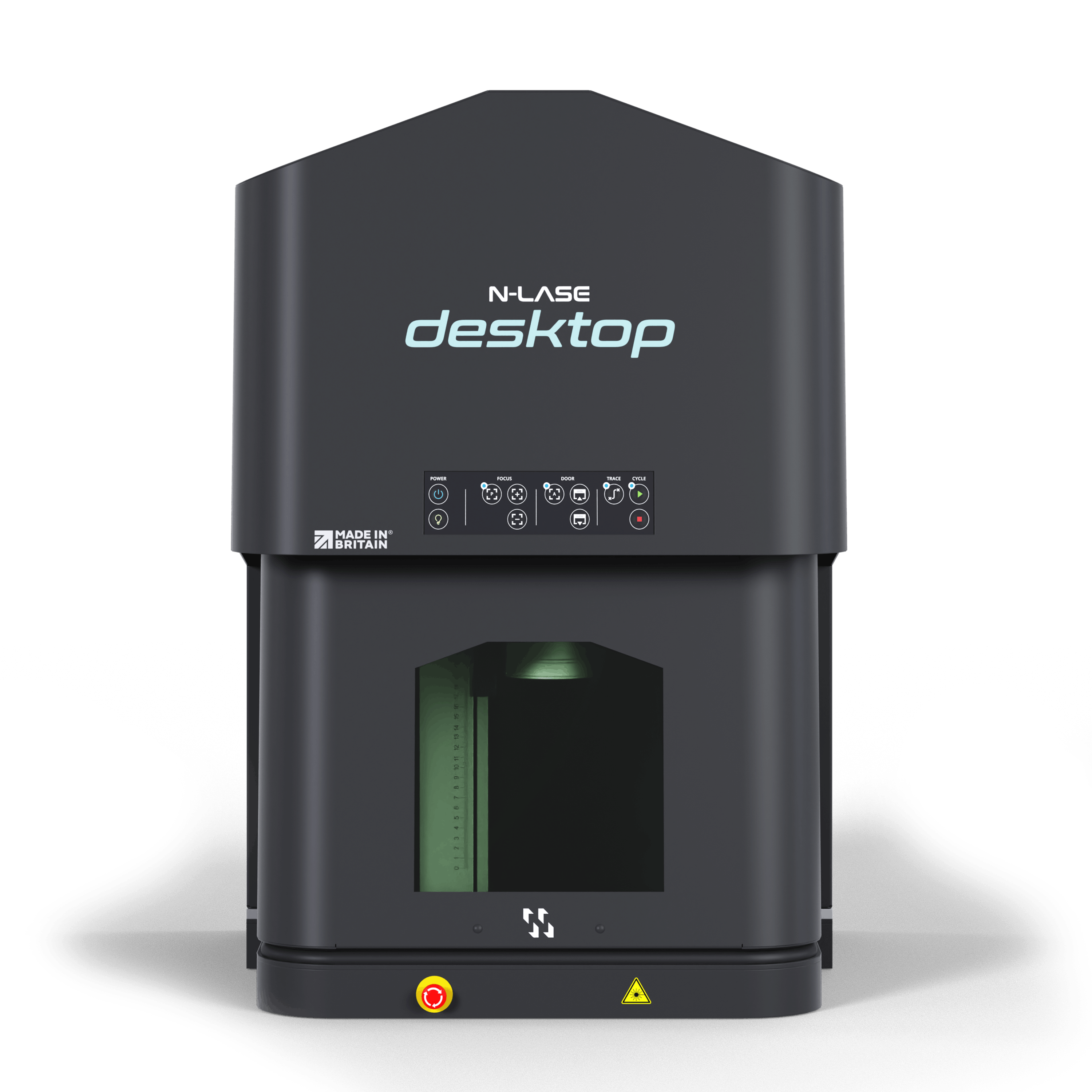

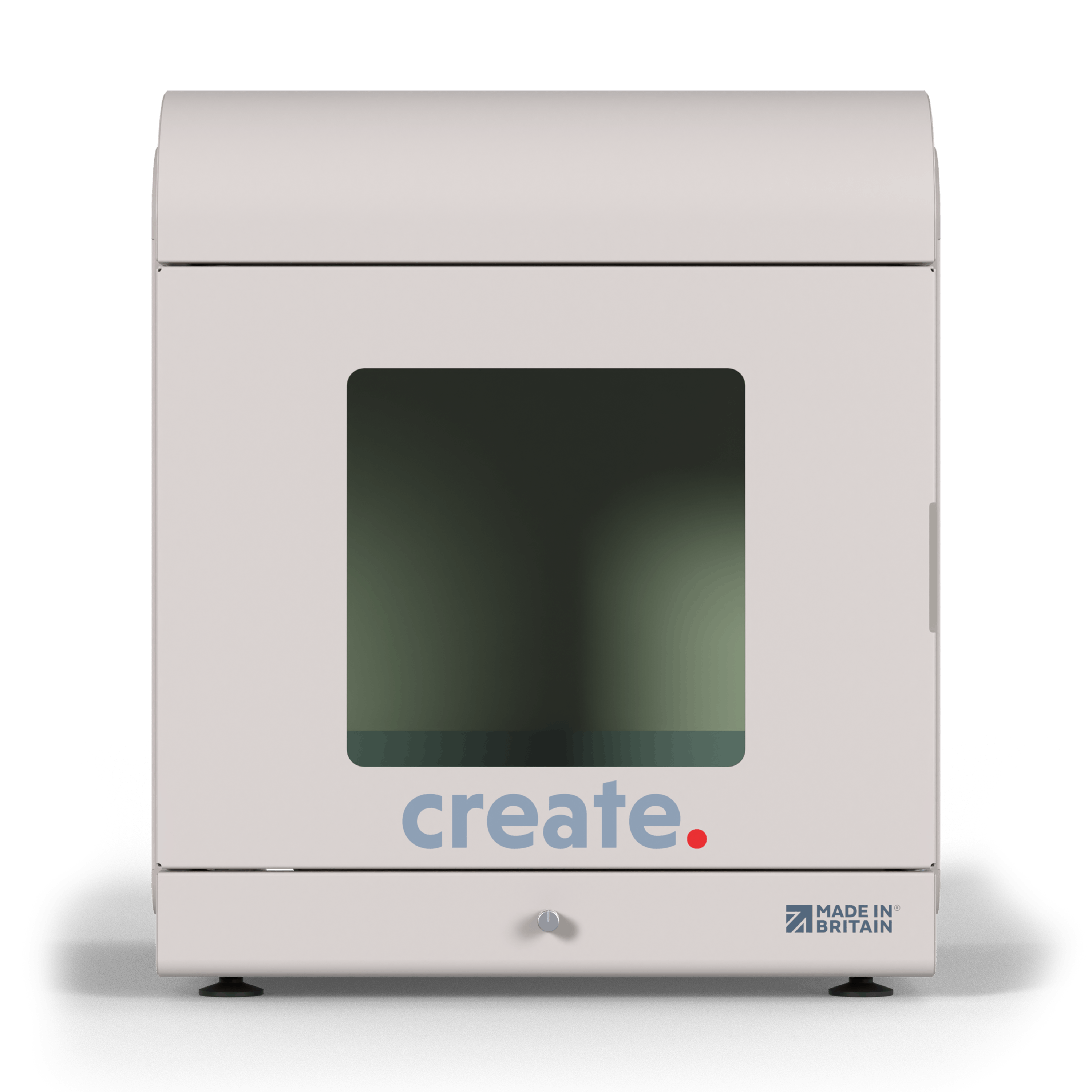

The marking and engraving of metals parts have practically become an essential part of working with metals, whether it is for traceability purposes or as a visual enhancement. To this end, laser engraving machines for metal have become a standard tool for industries that heavily use metals such as engineering, manufacturing, and jewellery making, among others.