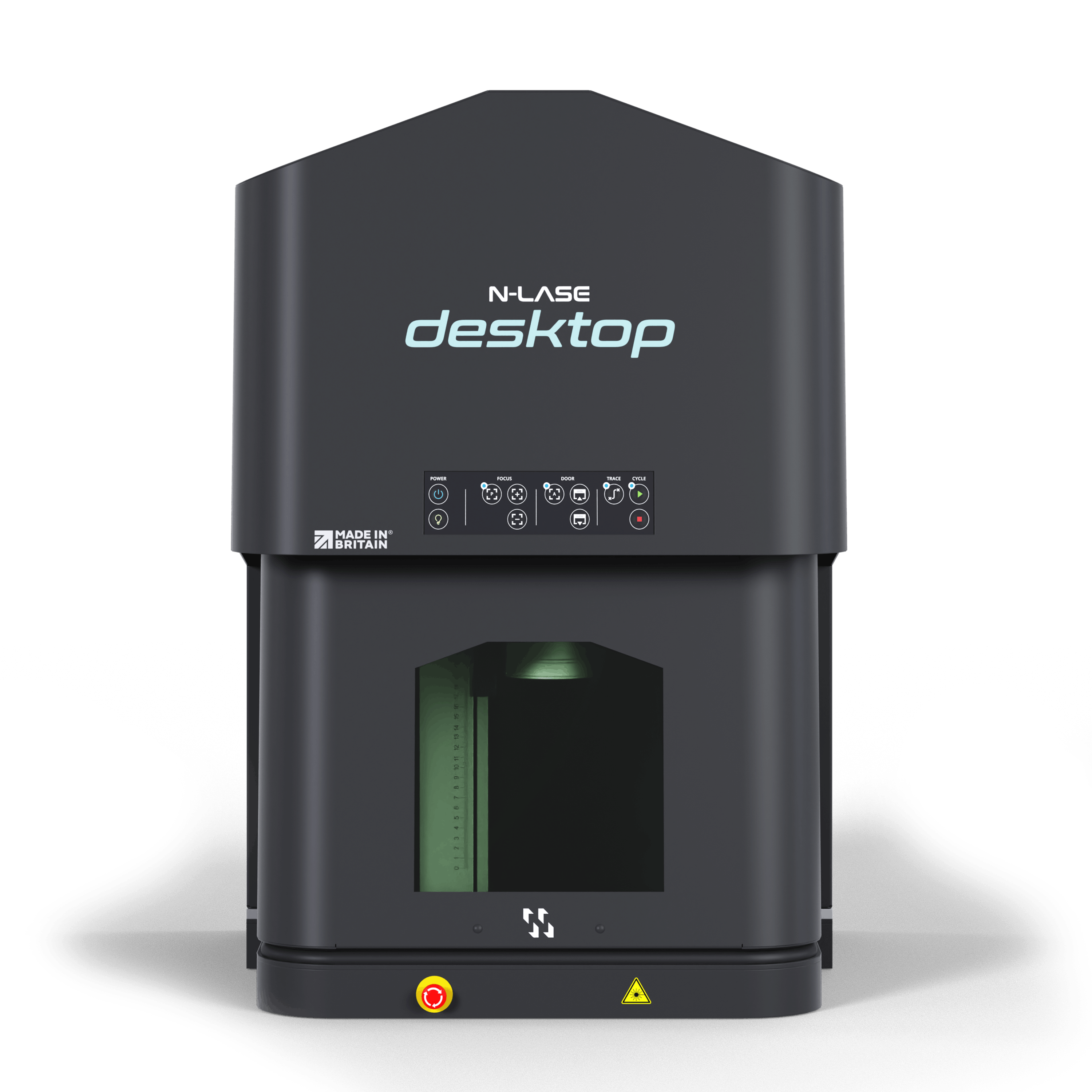

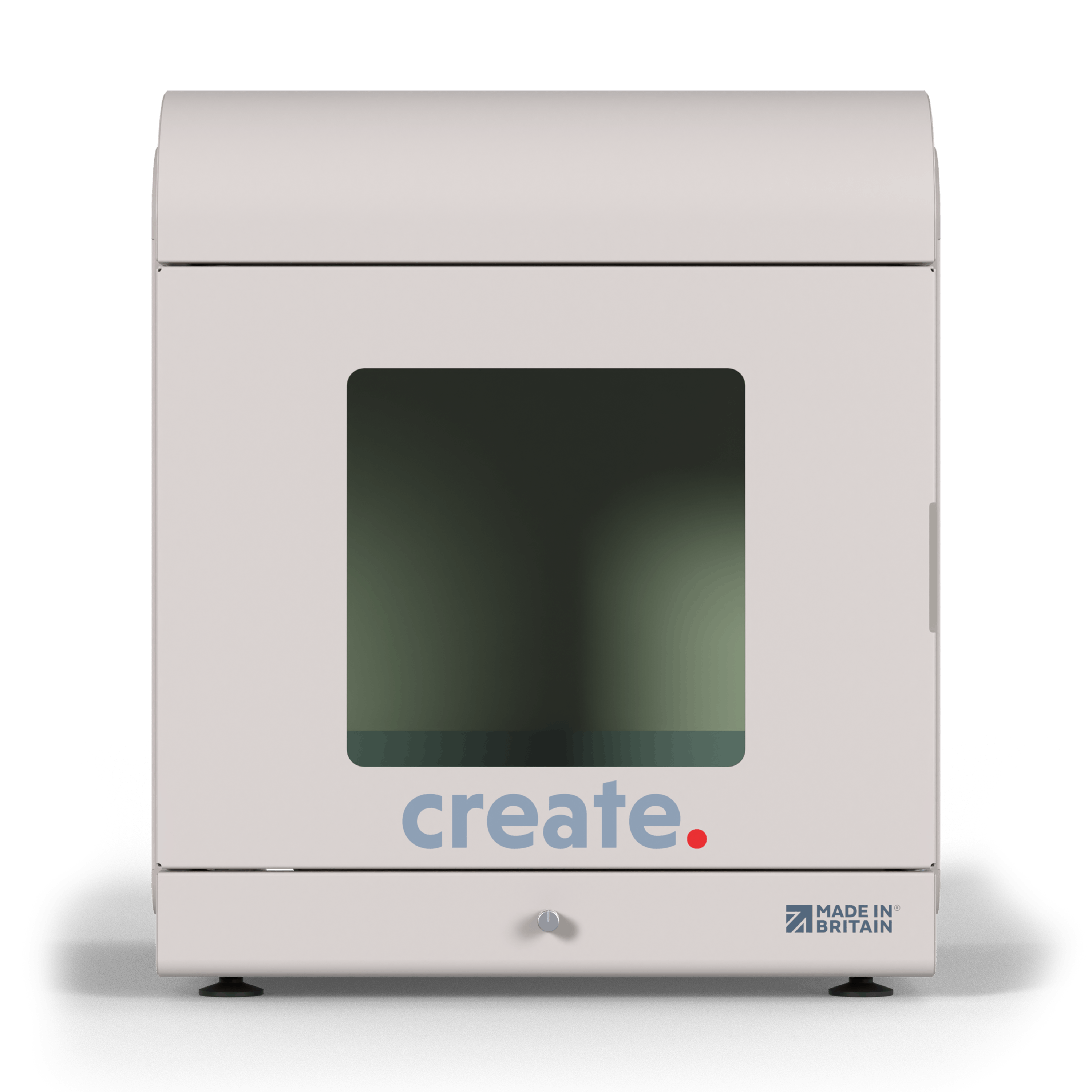

Our fiber laser systems offer an out-of-the-box solution for engraving metal, coated metal, plastic, glass, ceramic and organic products, making the machines a cost-effective manufacturing solution. In manufacturing, a laser engraving machine is used for hundreds of different commercial and industrial products, from smartphones and watch batteries, to frying pans and toothbrushes.

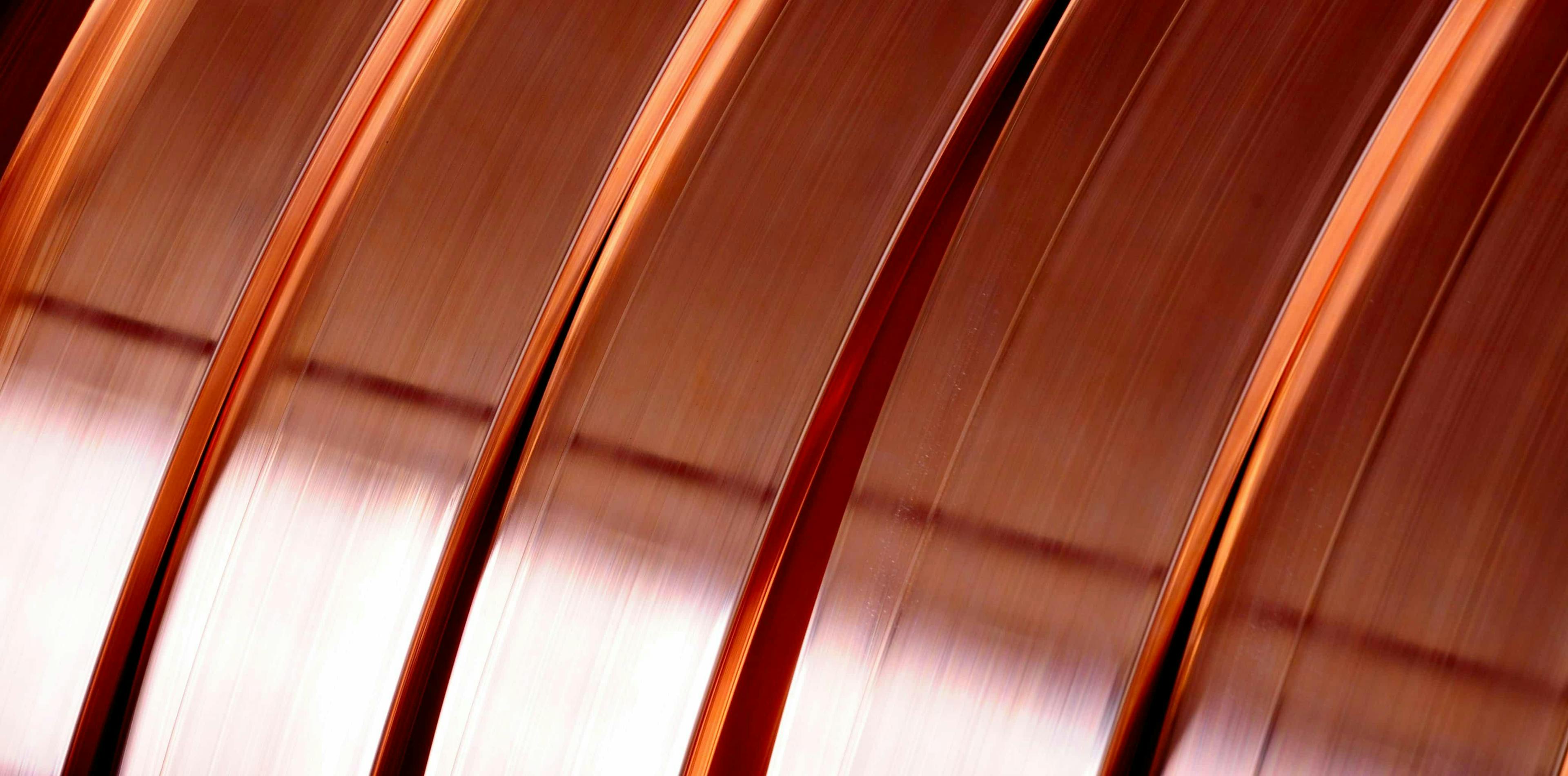

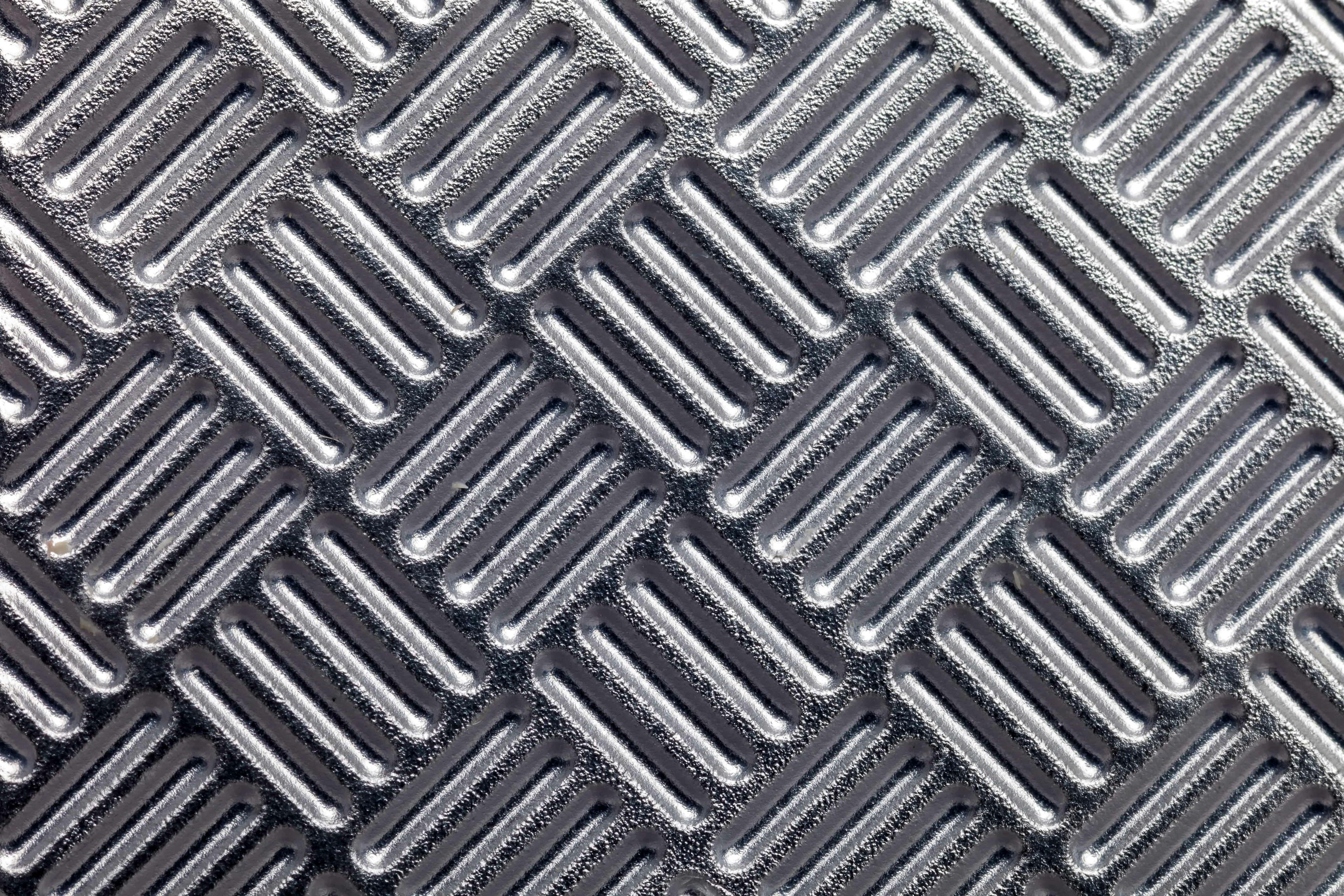

Fiber lasers are incredibly versatile tools that can mark a range of materials. Metals such as stainless steel, titanium, anodized aluminium, brass, and copper can all be marked with a fiber laser with the process of laser marking preferable to traditional methods as it doesn’t alter the composition of the material or cause any damage to the surface. The result is a sharp and accurate engraving of the material, whether it’s text, a logo, or a design. The type of materials that can be marked with a fiber laser also includes plastics such as polycarbonate, PEEK, ABS, and acrylic. Imprints can also produced in rubber, silicone, and cotton fabrics.

With a fiber laser, you can create anything from serial numbers and bar codes to personal messages and company logos. The options are virtually limitless. The greatest advantage of using a fiber laser is that it leaves a permanent mark that can last for years, thus eliminating the need to regularly make new engravings.

We work with clients every day to carefully assess their application requirements and help them choose the right laser; allowing you to achieve reliable, precision results every time.