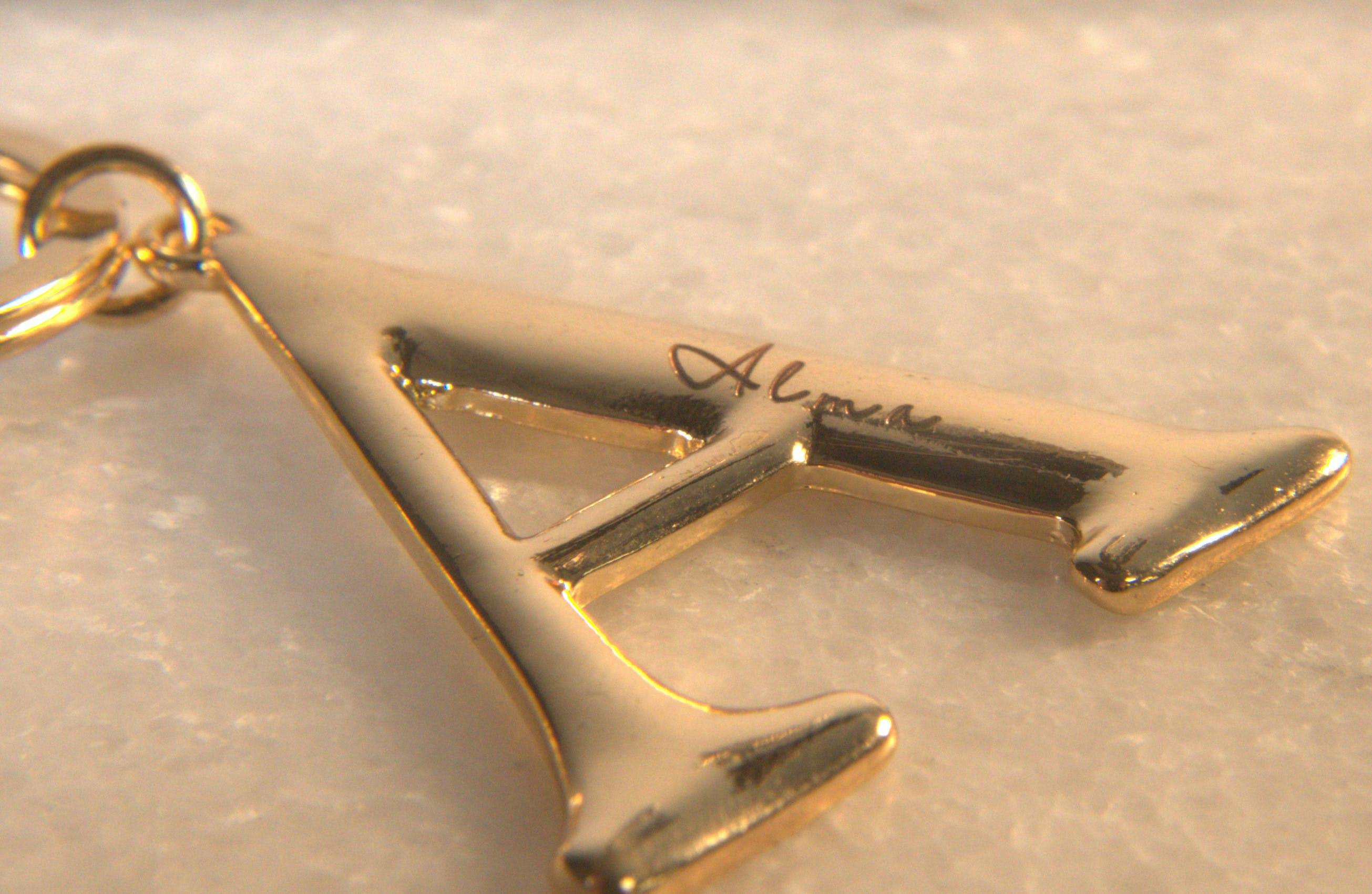

Personalised Laser Engraving in Gold Applications

Since gold has become more accessible, with most consumers instead preferring their pieces to have a higher degree of personalisation and customisation. Pendants, rings, and charms are considered more valuable when they has a person’s name, initials, or other personal inscriptions.

Since gold has a highly reflective surface, a pulsed fiber laser is preferred to laser engrave gold. By using a laser with a higher energy density, the heat is quickly absorbed by the material. The parameters of a pulsed fiber laser can be adjusted to work with very delicate materials such as extremely thin or hollow gold items.

Pulsed fiber lasers have become the standard technology used specifically for gold items. A fiber laser concentrates high energy in a fine laser beam, allowing gold laser engraving with highly intricate and detailed designs. With a higher degree of control, a pulsed laser fiber does not damage the surrounding material, resulting in custom engraved jewellery with a clean finish.

Hallmarking is a process by which jewellers leave unique marks on their pieces as a sort of “trademark”. This process was traditionally done by using steel punches, but laser engraving technology has provided jewellery makers with the ability to create hallmarks without causing damage or distortion to the product. Given the soft nature of gold metal, the non-contact engraving process is the best method to ensure that the item does not suffer any secondary damage. An automated laser marking operation ensures that results are accurate every single time.