The Solution.

So, how did we help?

Following an initial consultation with our Sales team, Steve was invited for a demonstration onsite here in Whitchurch.

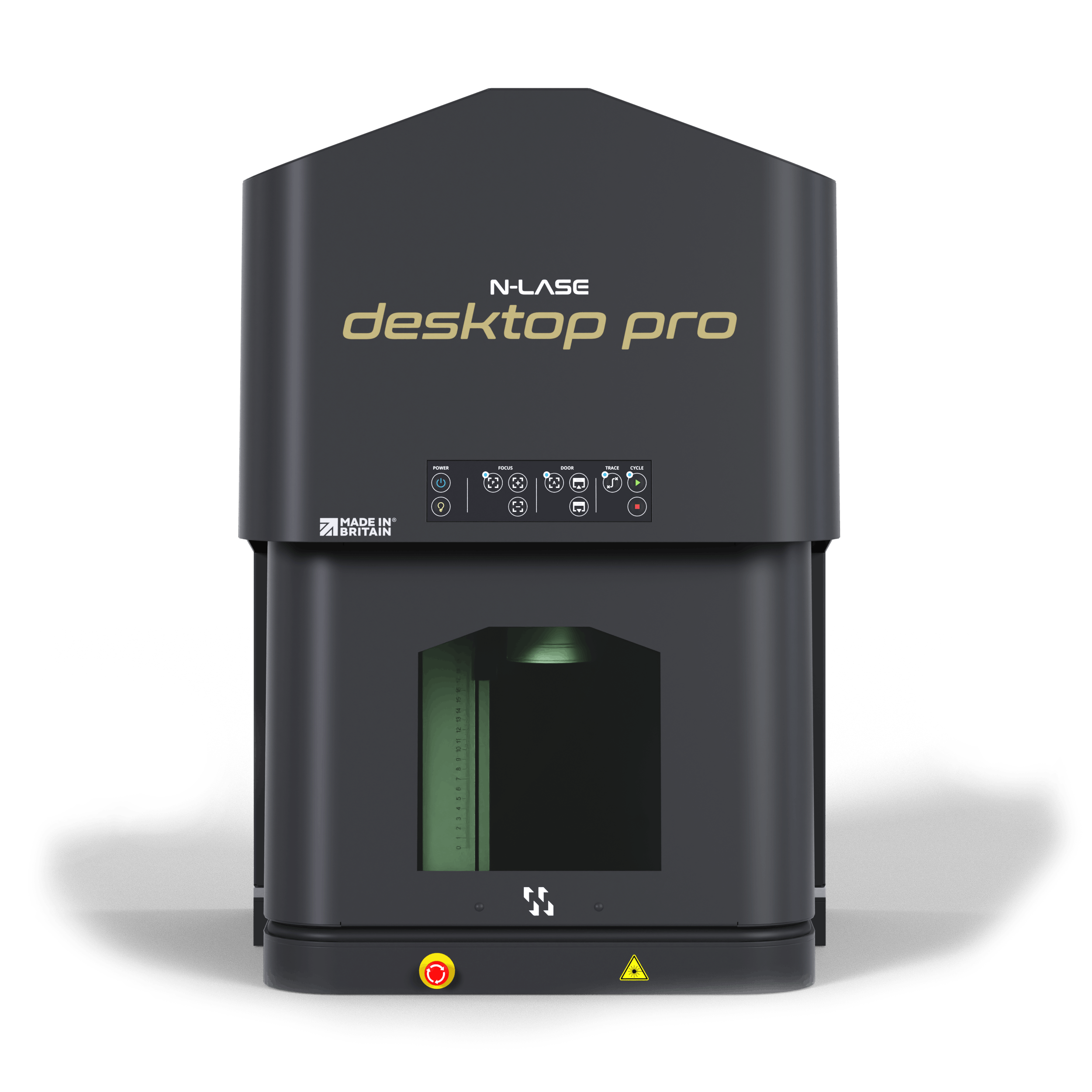

Steve was keen to specifically see our Desktop Pro in action, so we got one set up with a rotary attachment enabled, ready to mark some parts.

Whether it is onsite here in Whitchurch, or at the customer’s premises, our demonstrations are a great opportunity to witness firsthand the power and capability of laser technology, especially when we can demonstrate applications on the customer’s own samples.

Following a demo, the N-Lase Desktop Pro was identified as the right solution for Wealdpark. The Desktop Pro is compact but still feature-rich, with a robust enclosure to withstand the harshest manufacturing environments. It's Class 4 override means that, whilst wearing adequate laser safety equipment, the laser can be operated with the door open. It’s also rotary-ready, so round and cylindrical parts can be marked with ease. The Desktop Pro is a great all-rounder and was exactly what Wealdpark were looking for.

Having found the right solution, our production team got to work building the laser here at our HQ in Whitchurch – we are proud to have the ‘Made in Britain’ badge on all our laser systems.

Our engineers installed the machine at Wealdpark Ltd and provided a full day of training for the team, to ensure that they were able to get the most out of their machine with knowledge of basic functions and mark settings. Our in-house tech team in Whitchurch are always on hand at the end of the phone should our customers need additional assistance or any technical support.