Permanent

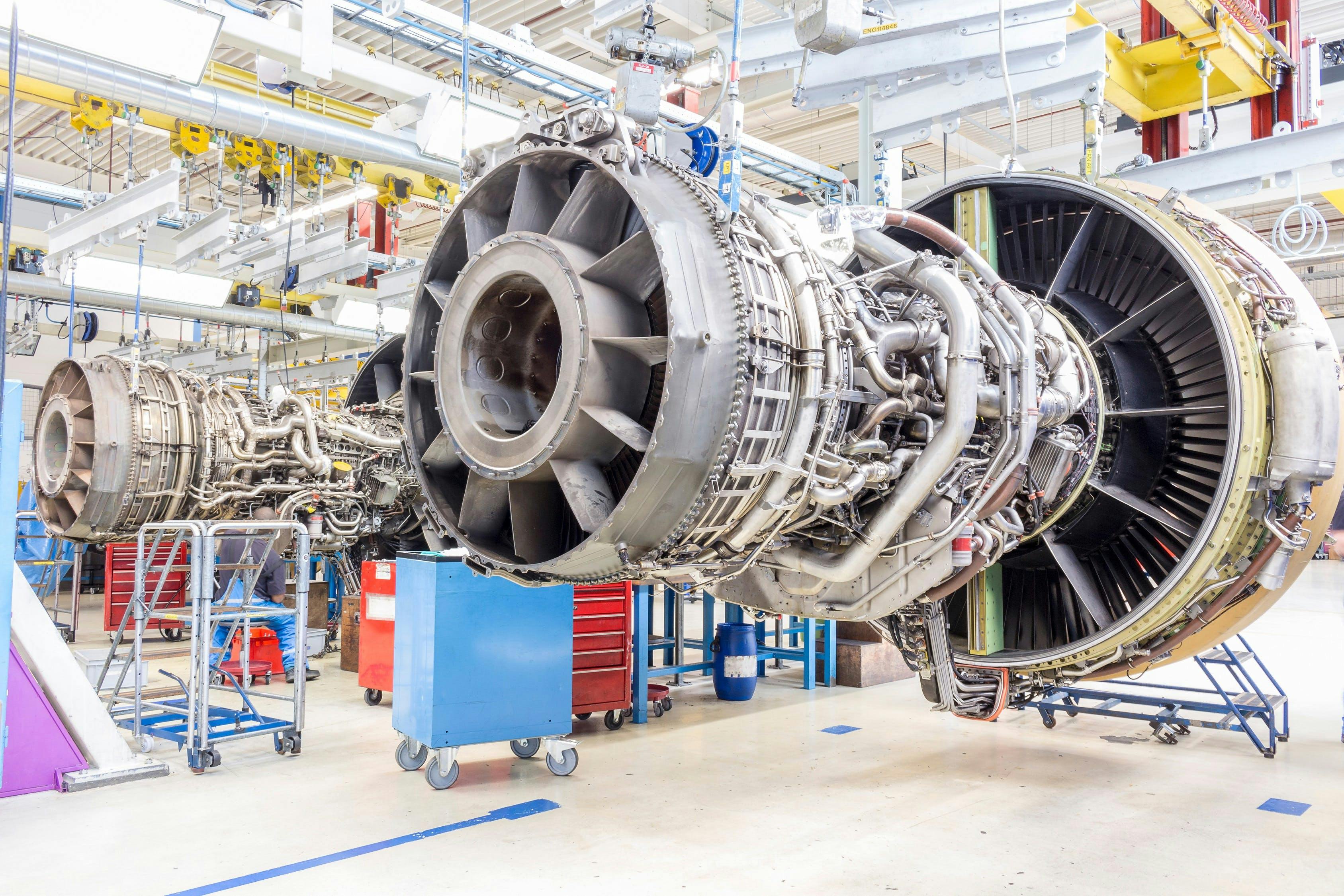

Aircraft, whether commercial or military, have lengthy operating lifespans; airline aircraft have an average age of 20-25 years. Over the course of such lifespans, regular maintenance and repair of the aircraft will be commonplace, as well as a steady interchange of approved parts. As such, the need for aerospace part serialisation and traceability are the most crucial features of aerospace maintenance and manufacturing.

The parts used in aerospace engineering require a range of materials for various applications. Each material requires marking that does not damage its integrity at the time of marking, as well as being resistant to the temperatures and friction levels that particular part will endure. Needham Laser Tech’s systems make permanent marks on:

- Stainless steel

- Soft metals

- Hardened metals

- Alloys

- Titanium

- Titanium alloys

- Brass

- Copper

- Carbides

- High-speed steels

- Aluminium

- Anodised aluminium

- Coated metals

- Precious metals such as silver and gold

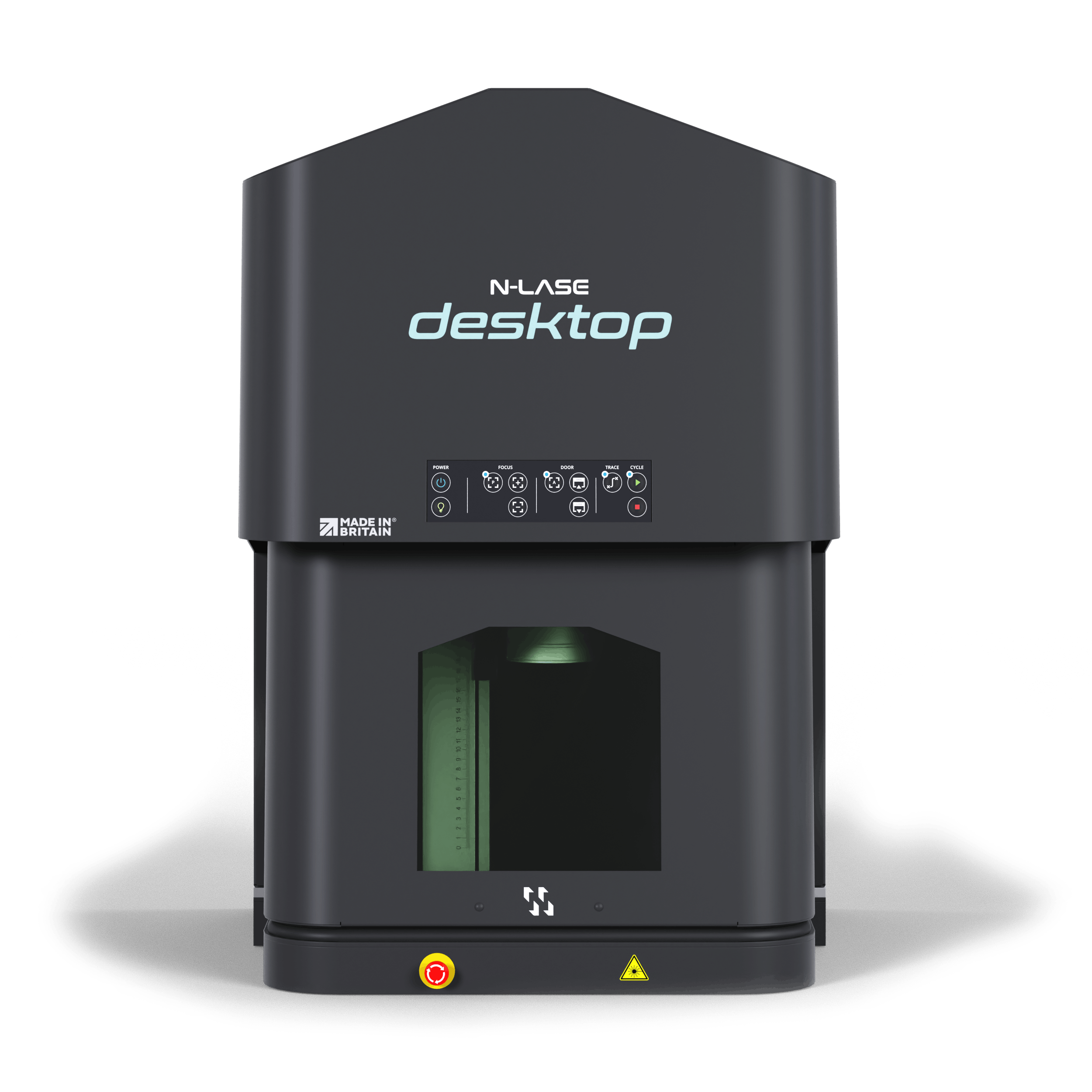

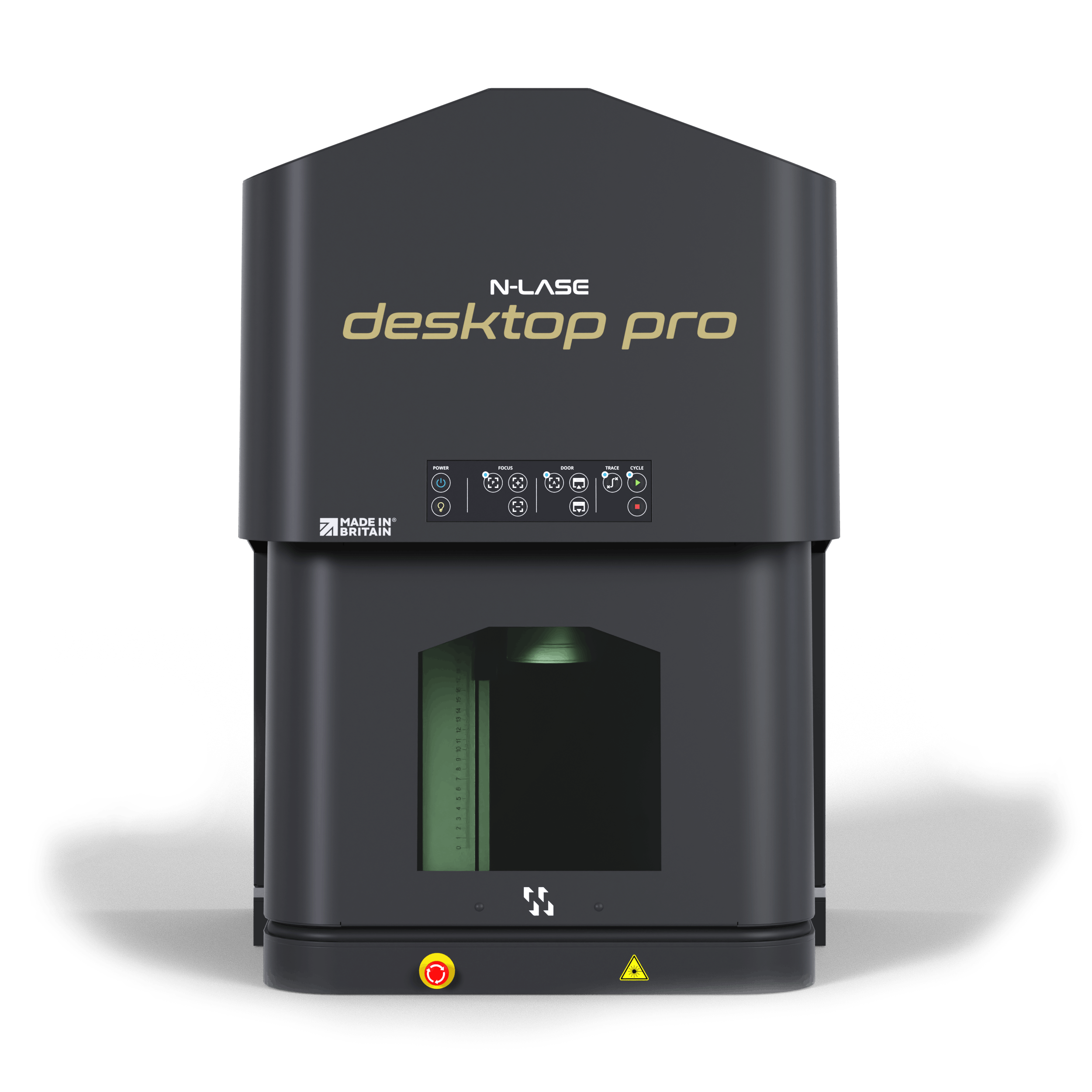

In contrast to more traditional methods of marking, a laser engraving machine does not require consumables such as inks, chemicals, or pastes.

Traceable

A strong traceability system is an essential aspect of quality monitoring for engineering part makers. The use of a metal laser marking system guarantees that these traceability markings stay permanent and readable for the part’s lifespan, which is especially important for parts that are subjected to a lot of friction and heat. Needham’s accurate laser systems ensure that your aerospace parts are permanently traceable and identifiable.

Safe

Not only is the quality at the pinnacle of industry standards, but our laser engraving machines also require no contact with the materials, which essentially negates the risk of damaging the materials engraved. This is vital for parts that will be used in the harshest environments - including extremely high temperatures and levels of friction. The laser etching will not be compromised by the part’s exposure to such factors, allowing for permanent traceability.

Cost-effective

Alongside a no-contact marking application, our laser engraving systems require no consumables, which is a significant cost in other engraving application forms. The full automation reduces the need for human interference - and the little need for maintenance makes laser engraving a much more economical option than more traditional engraving forms.

Superior metal and material engraving

A laser engraver's metal uses are as diverse as its aeronautical applications. Permanent markings may be made on stainless steel, soft metals, hardened metals, alloys, titanium, titanium alloys, brass, copper, carbides, high-speed steels, aluminium, anodized aluminium, coated metals, and precious metals such as silver and gold using a metal engraving machine. Switching from one metal to another will be as simple as adjusting laser parameters on the accompanying software with the correct equipment and a competent operator at the helm.