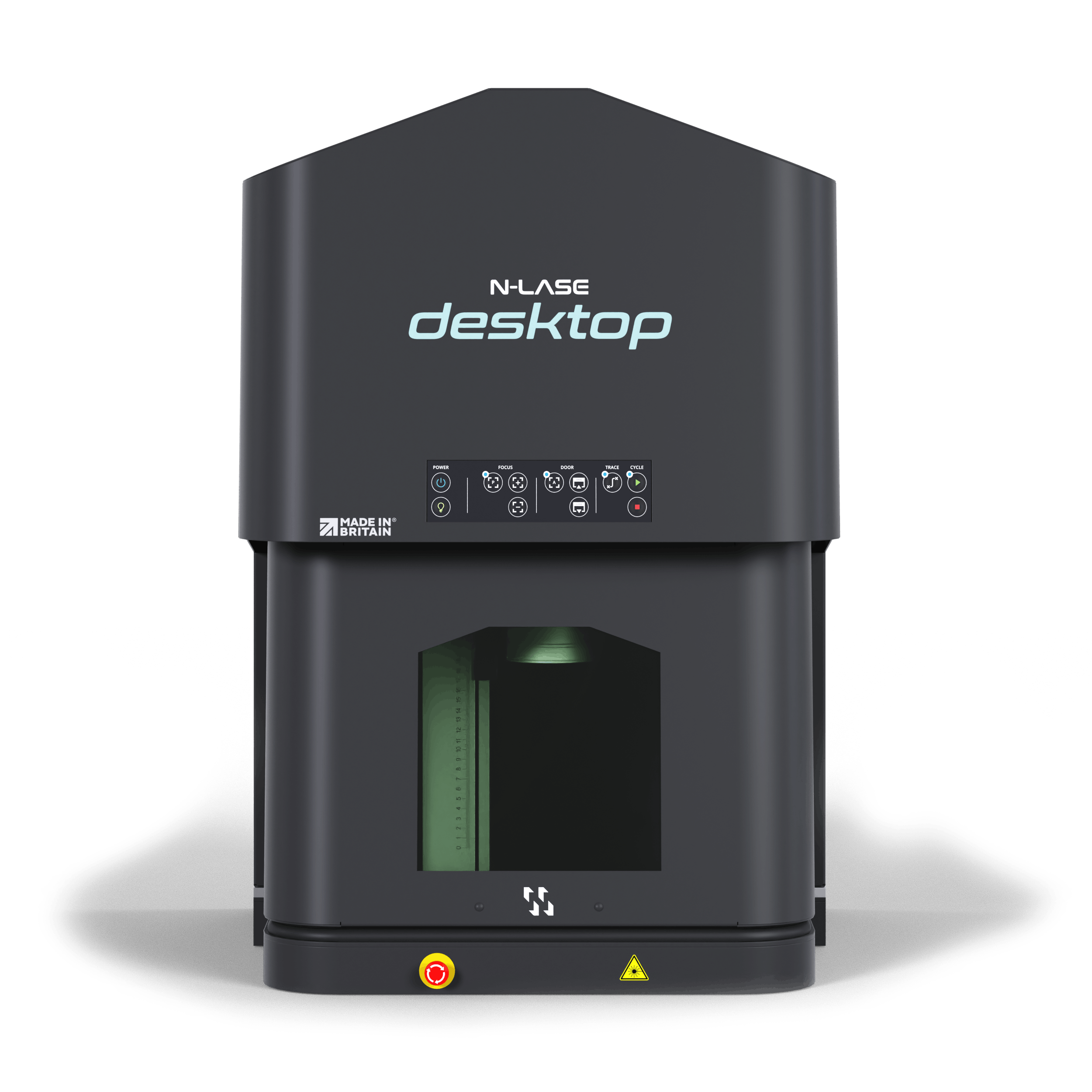

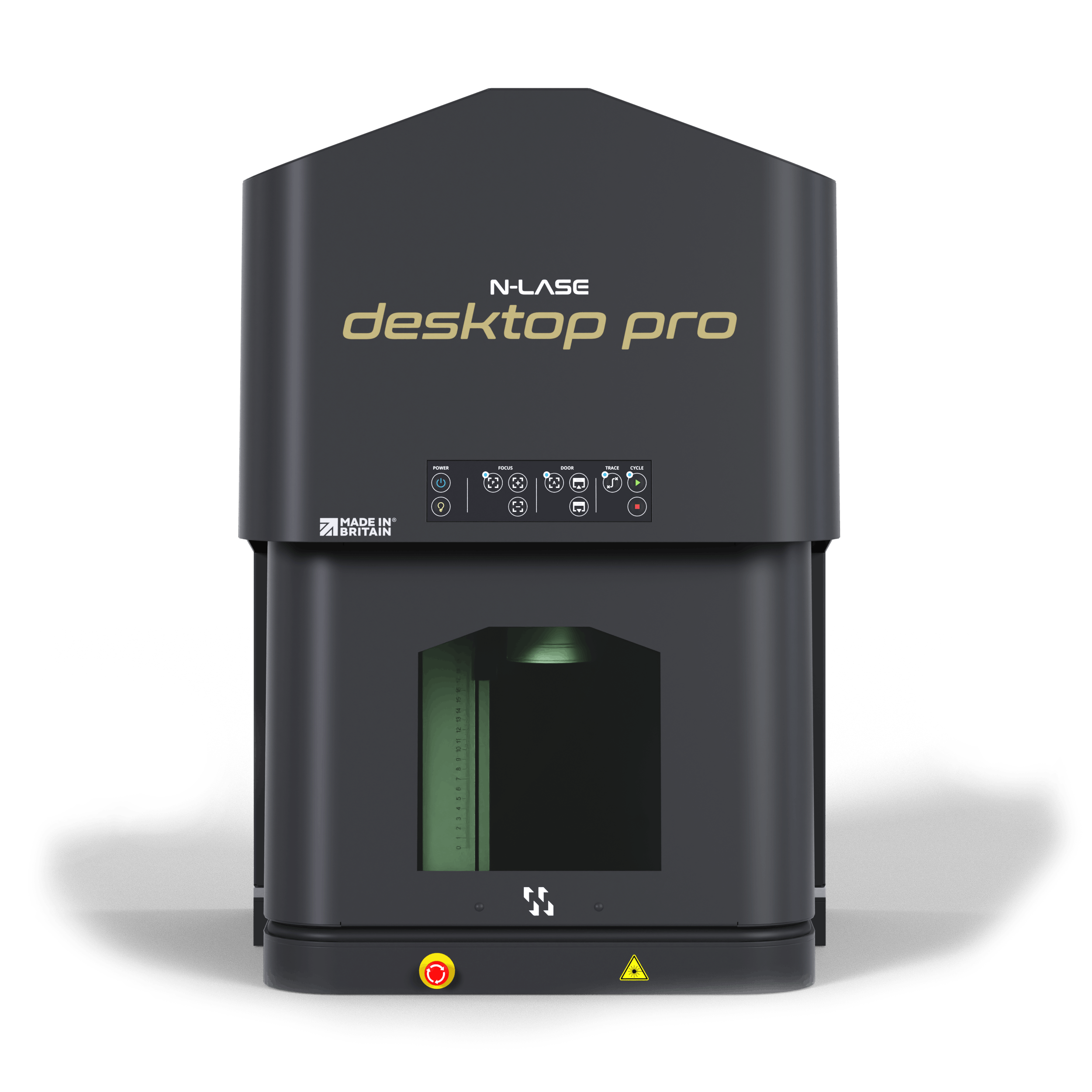

The demands of the Engineering Industry

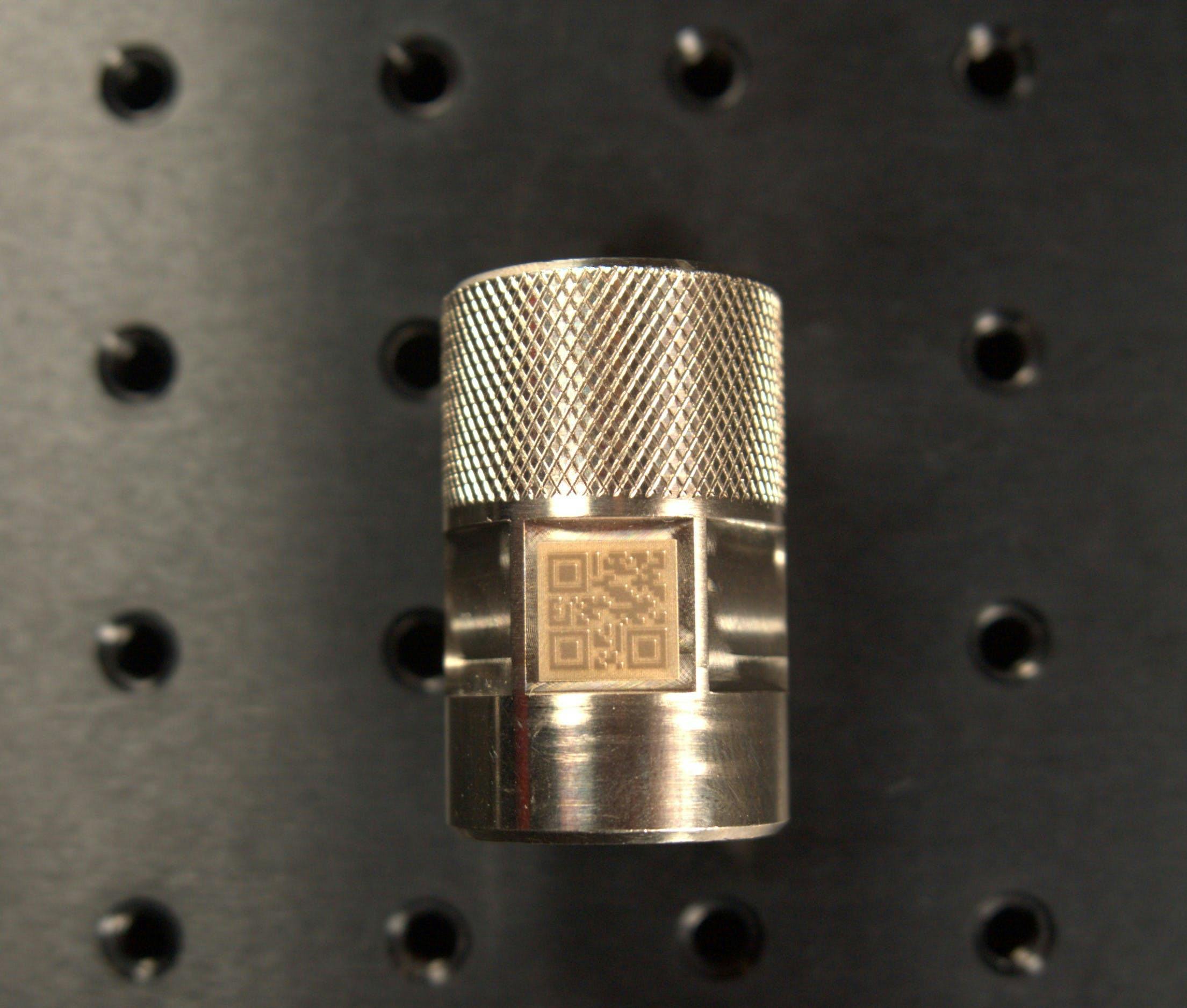

A laser engraving machine can also be used to make legible marks on common engineering tools such as callipers, wrenches, and drill bits. Some of these parts are incredibly small, making laser marking a particularly suitable technology for marking characters that are still legible at 1-point size.

In the case of callipers and other measuring tools, the precision and accuracy of the markings are key. The automated process of a metal etching machine delivers essential repeatability and consistency, ensuring that engineering measuring tools have ticks and readings that are marked and positioned accurately.

Metals that are etched using lasers do not have to undergo any pre or post-treatment and being almost fully automated, the laser system delivers consistent quality every single time. Due to the small resolution that can be achieved, accurate and legible marking is possible on even the smallest of parts. Laser marking also provides practically unlimited design opportunities, including coloured laser markings.

Laser marking is a non contact technology, reducing material stress. There is no need to fix the materials to the engraving platform, so items can be shuffled in and out quickly, reducing production time. No contact means reduced secondary damage, ultimately impacting your bottom line with cost savings in production.