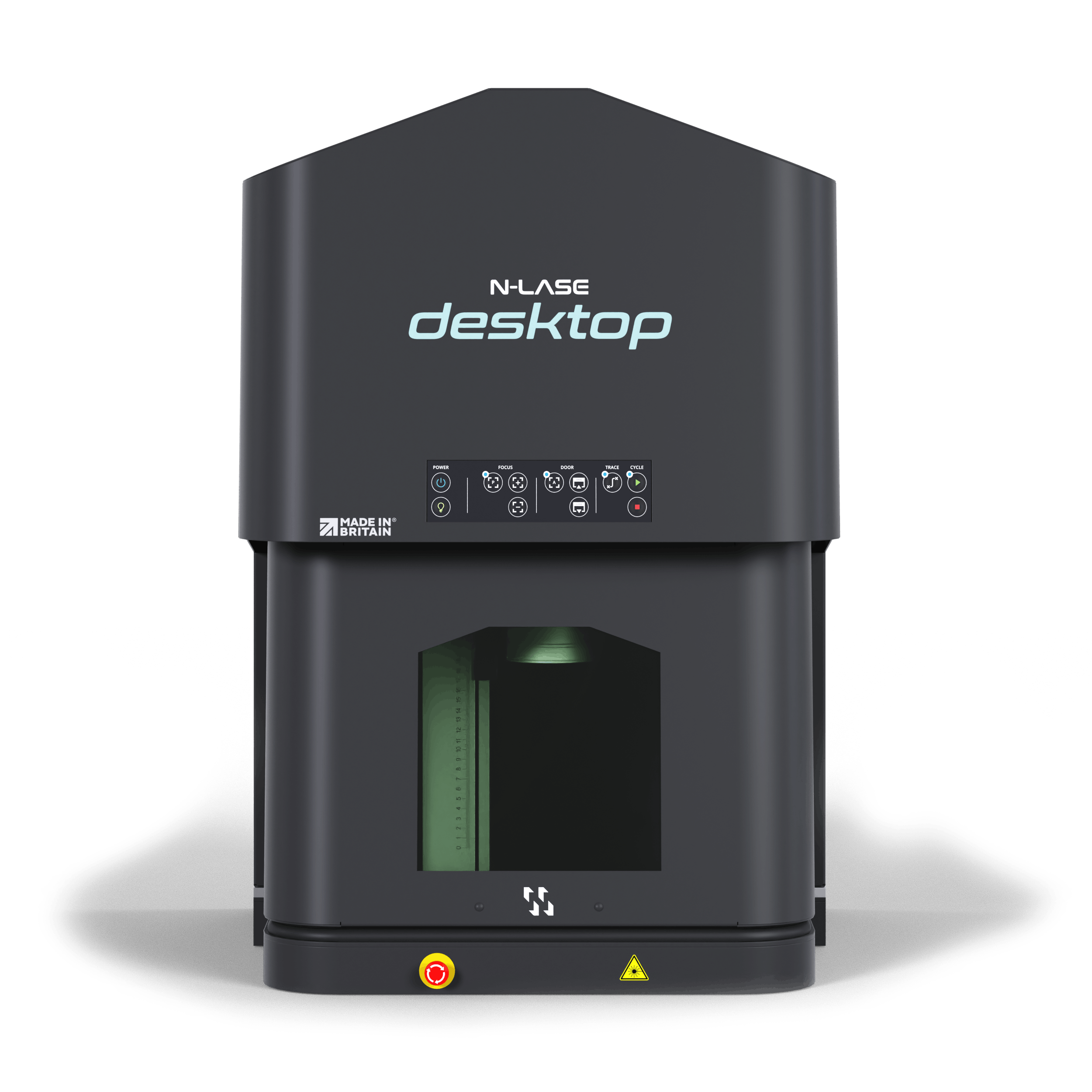

N-Lase Desktop

The N-Lase Desktop is our entry-level laser marking system for industrial identification applications, perfect for marking, etching, engraving and annealing all metals, coated metals, plastics and some organic materials.

The Desktop is the ideal solution for low to mid-volume throughput and is an affordable alternative to more traditional methods of marking, such as dot peen, electrochemical etching or hand marking. Despite being entry-level and affordable we haven’t sacrificed on quality or efficiency; our N-Lase Desktop comes with either our 20 Watt or 50 Watt MOPA fiber laser with a MTBF of 100,000 marking hours and a 3-year comprehensive warranty, as standard.