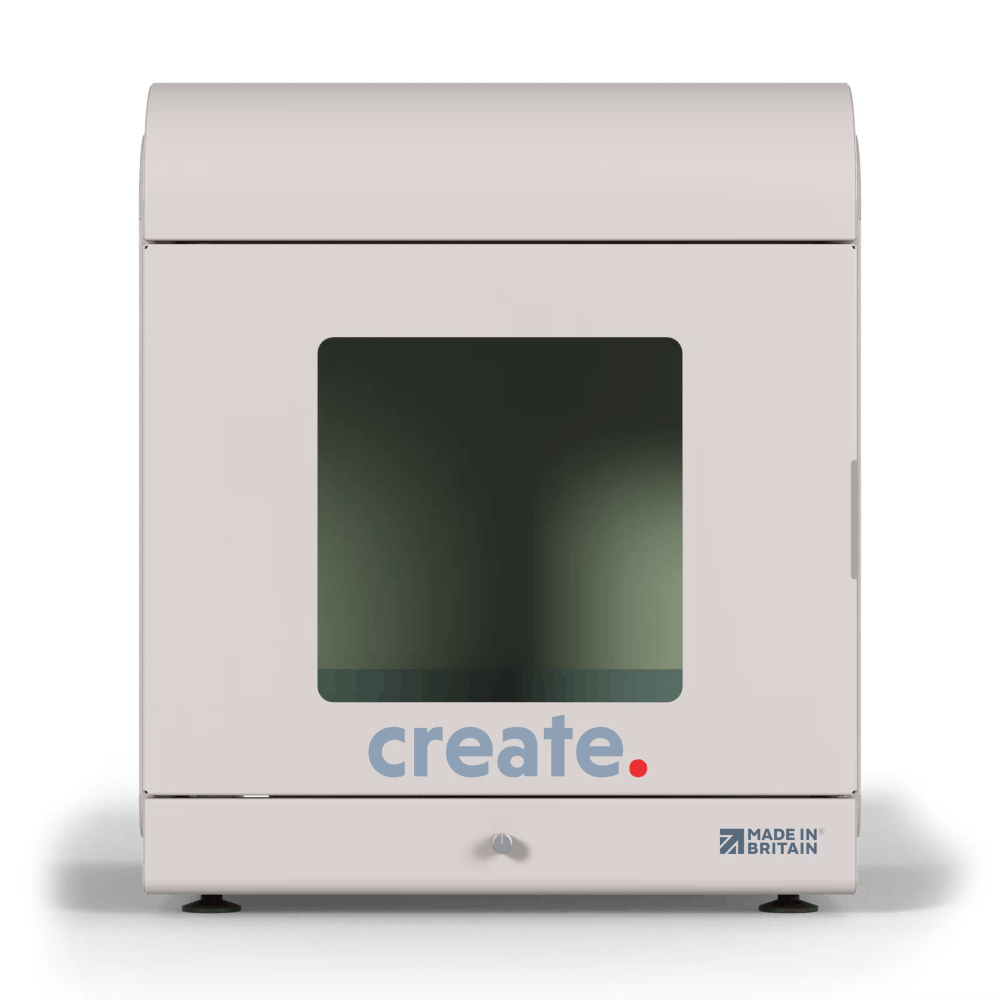

for your shop floor

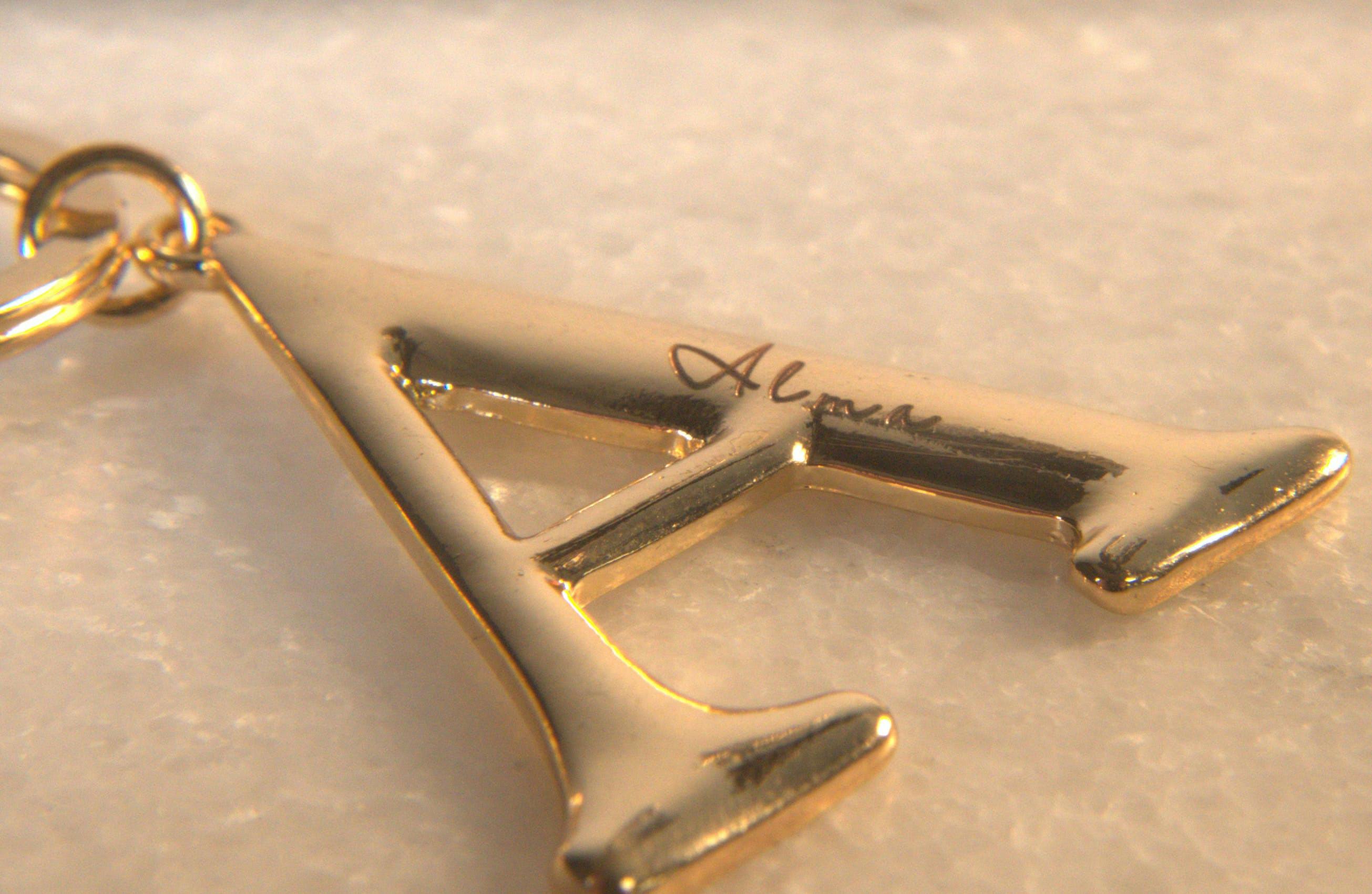

The Create laser allows for instant next-level personalisation in your store. Bring the theatre of laser engraving jewellery to your customers, allowing them to witness their gifts being marked right in front of their eyes. Instant personalisation to take home immediately is the future of jewellery.

The Create is not only a simple and neat package perfect for small shop floor spaces - it also houses a bundle of excellent features, including a rotary for engraving curved surfaces such as rings, and also a positioning camera so you can see EXACTLY where the mark will hit your part. The software is super easy to use and understand, and should you need it, we have an all-UK support network on hand.

And because there are no consumables with your Create, there is no additional footprint when using your laser engraver. The energy consumption is impressively minimal too.

All of our lasers are manufactured here in the UK, and we are proud to align our UK design and manufacturing with the UK’s rigorous regulatory laser safety requirements.