The 2023 FIA Formula One World Championship introduced a new set of regulations that have impacted the way each team uses car parts over the course of their season. The FIA, the sport’s governing body, regulates the sport and ensures teams are limited to a certain number of car and engine parts.

Given the huge number of car parts used to build a Formula One car, each part must be traceable. The ability to trace each part is vital for engineers to understand the individual part’s batch number, lifecycle and product label - each item of information provides an overview of the parts that are being used at any given time in a car, allowing for instant inventory management data control.

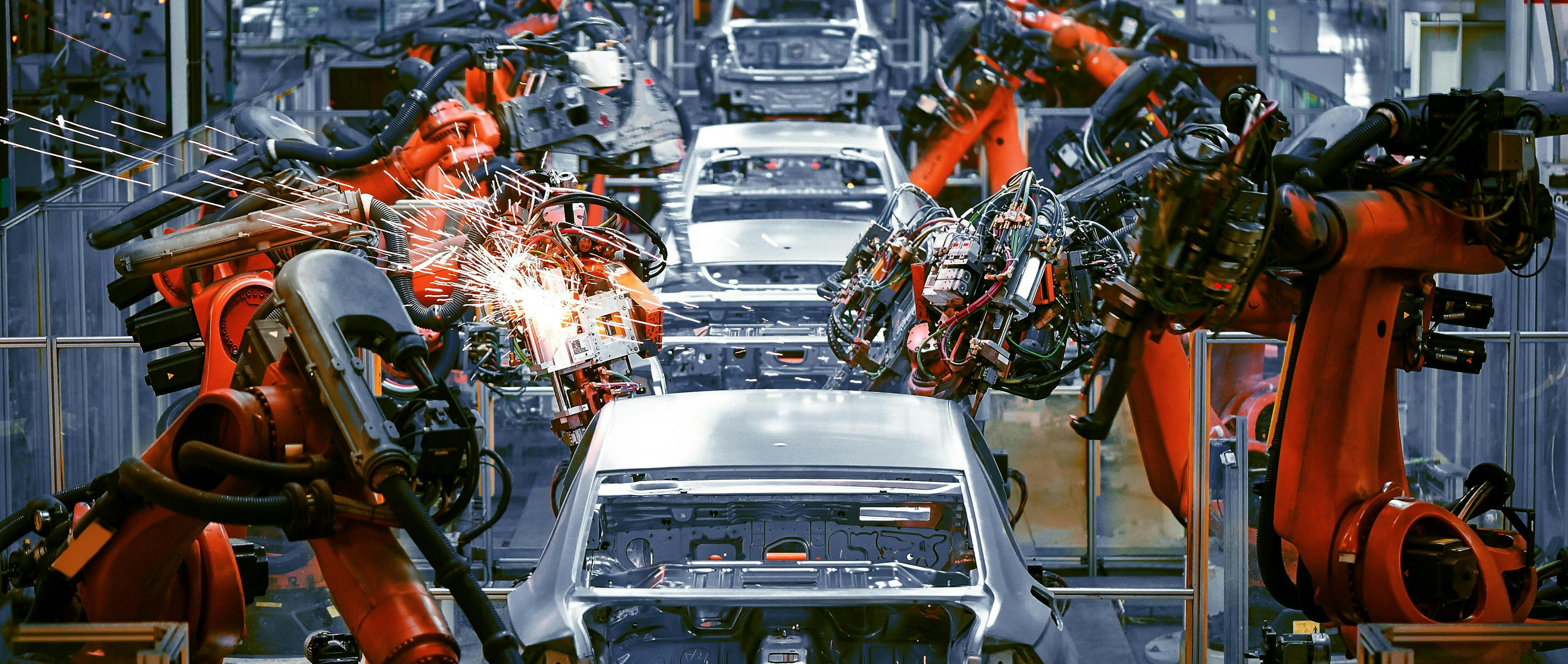

The nature of Formula One means that each car part is under an enormous amount of stress and friction, and crashes are frequent, resulting in damage to the car parts. Understanding which part has been damaged and replaced plays a vital role in ensuring that the car is fitted with safe components at all times.

The 2023 Formula One season has given the racing teams an opportunity to modify their car design and introduce revolutionary mechanisms to the car’s functioning, which has meant venturing into the unknown. Each car is limited to the hours during which it can be tested on the track, meaning that engineers must quickly adapt to real-time data and modify components to make the car as fast as possible. Such huge changes in the sport introduce natural challenges; in the build-up to the new season, no team can guarantee that their car will function exactly as intended, and mechanical failures are frequent. Therefore, there is an expectation that parts will fail and need to be replaced.

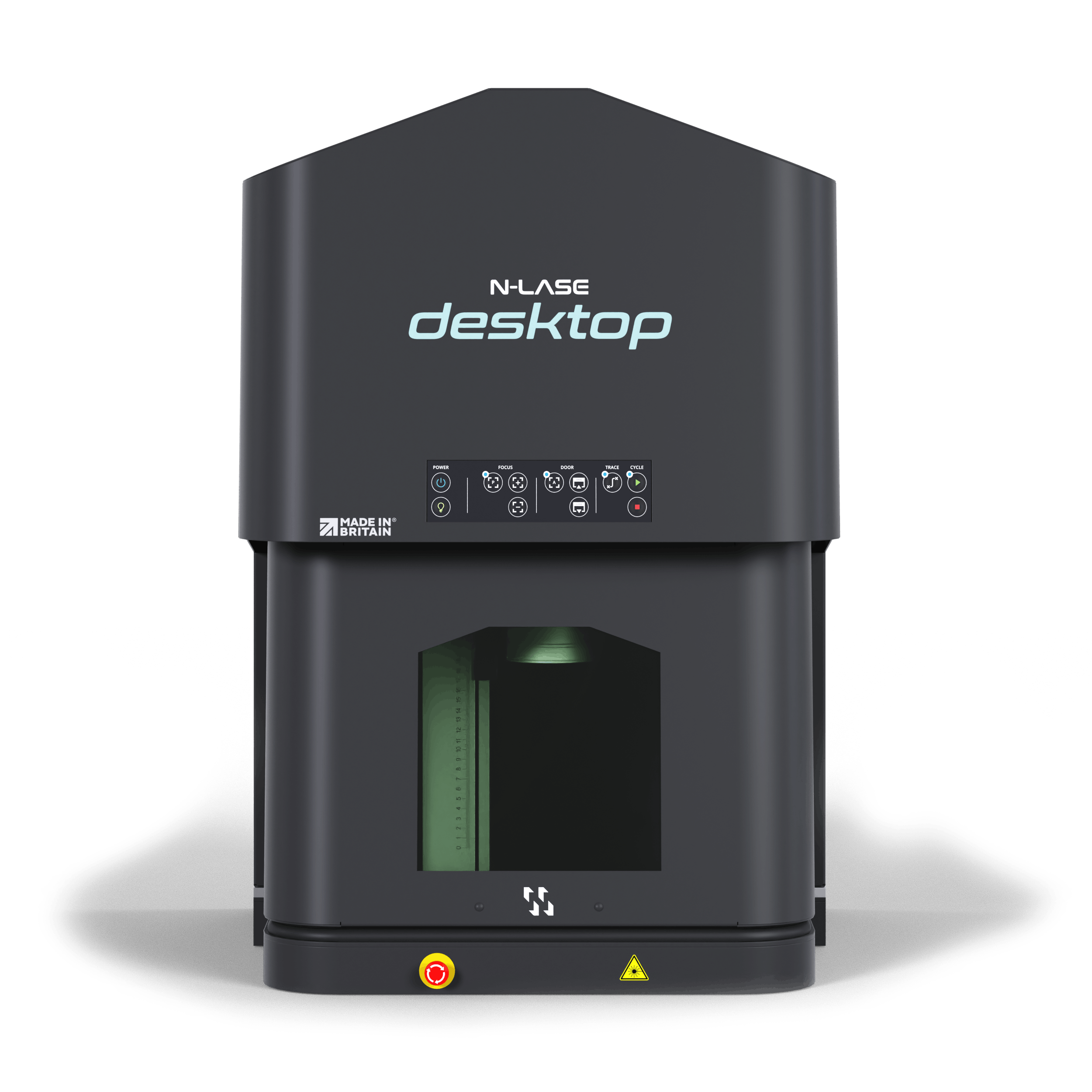

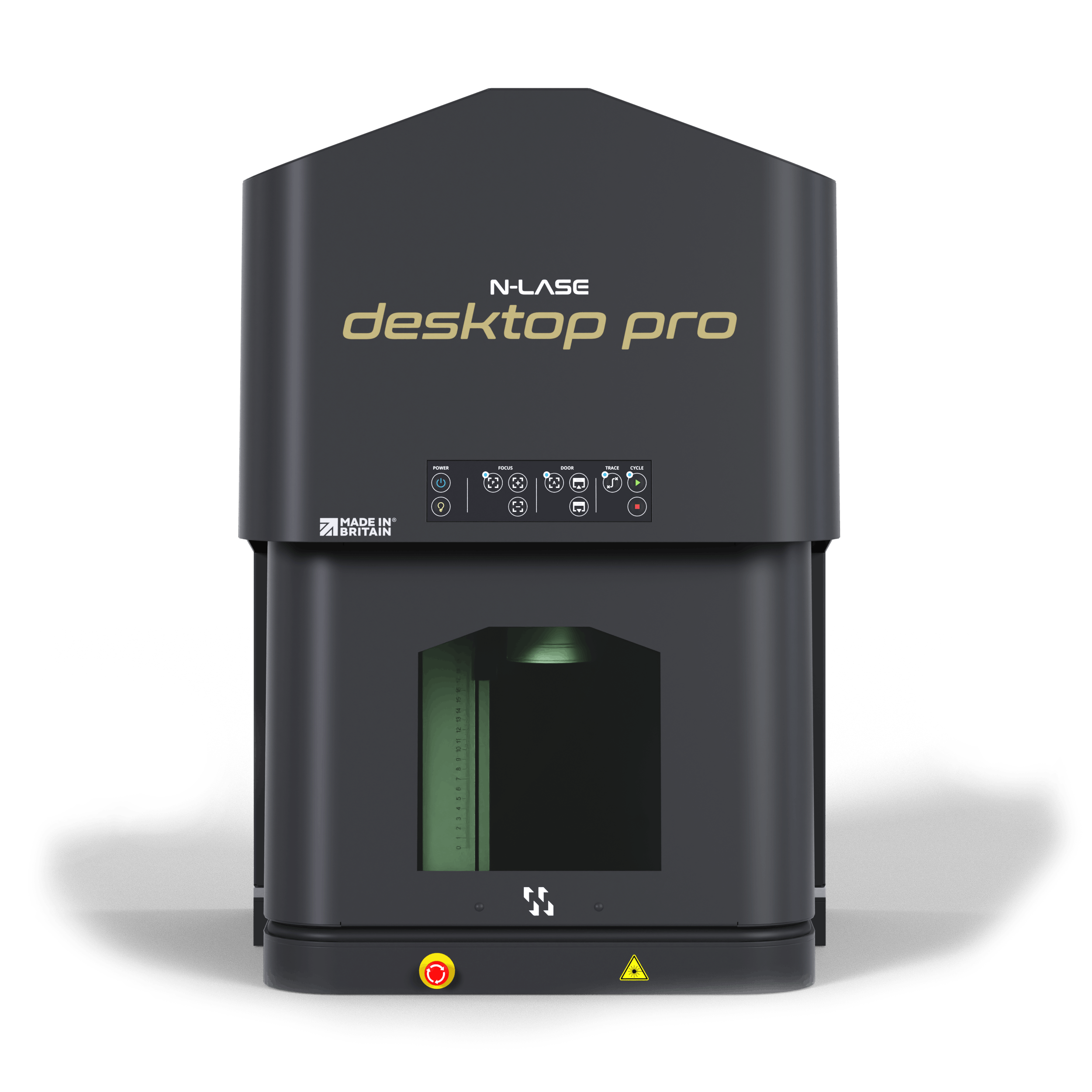

For the instant identification of individual parts and the ability to store data on the lifecycle of a component, Formula One teams are using Needham Laser Tech’s products to make precise, permanent marks directly on the car part. In the event of a batch failure, engineers can identify each part that needs to be recalled.

The traceability rules of Formula One are some of the most stringent in any industry. Thanks to the precise marking of Needham Laser Tech’s systems, regulating bodies and the competing teams can access data on any part at any moment, creating a fully-traceable inventory network that guarantees safety and compliance.