The Benefits

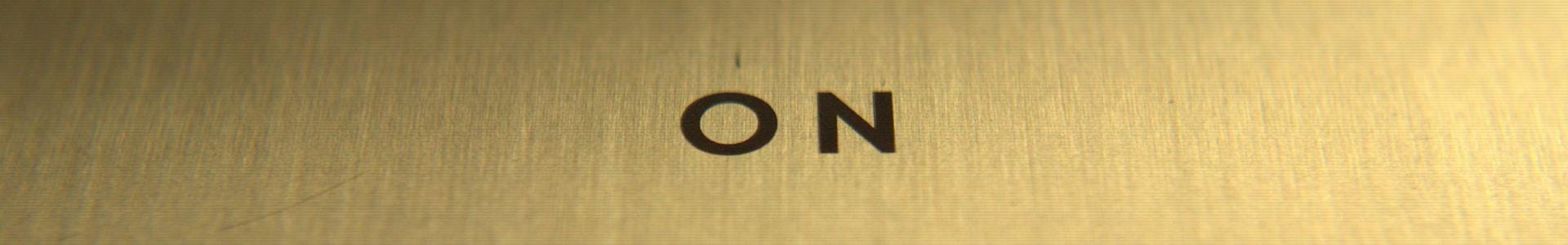

Laser engraving on brass offers several benefits over other traditional engraving methods. Firstly, laser engraving allows highly precise and intricate designs to be etched onto the brass surface. This level of precision is not achievable through other engraving methods, such as hand engraving or mechanical engraving. The laser beam can be finely controlled, allowing for precise cuts and detailed patterns to be created on the brass surface.

Another benefit of laser engraving on brass is the speed and efficiency of the process. Laser engraving can be completed quickly and accurately, reducing production times and allowing for high volumes of products to be produced quickly. This is especially important for businesses that require large quantities of personalised products or branding markers.

Additionally, laser engraving on brass is a non-contact process, meaning there is no physical contact between the engraving tool and the brass surface. This eliminates the risk of damage or distortion to the brass material, resulting in a clean and accurate finished product. Furthermore, laser engraving is a highly versatile technique that can be used on a wide variety of brass products, from small jewellery items to large industrial equipment, making it a valuable tool for a range of industries.