Cast Iron in Industrial Applications

Cast iron is an iron alloy that contains 2 to 4 percent carbon. Depending on the desired application, cast iron can also have a varying proportion of silica and manganese, plus trace amounts of sulphur and phosphorous. Cast iron is very commonly found in cookware, such as pans, griddles, and waffle irons due to its ability to provide even heating. It has also been used for construction and architecture and was actually used in a lot of bridges and railways before steel eventually replaced it as a common construction material. Nowadays, architectural use of cast iron is often limited to design elements such as garden features and ornamental objects.

Depending on the proportions of different alloying elements, the metal can have a variety of physical properties. Grey cast iron, the most commonly used cast iron, exhibits better compressive strength but has less tensile strength and shock resistance. White case iron, with a higher proportion of iron carbine, has superior hardness and abrasion resistance but is brittle. Ductile and malleable cast iron, as the name implies is softer and less brittle due to the presence of small spheroidal graphite particles. In any case, cast iron, in general, has a low melting point, which improves its machinability, and exhibits excellent resistance against wear and deformation.

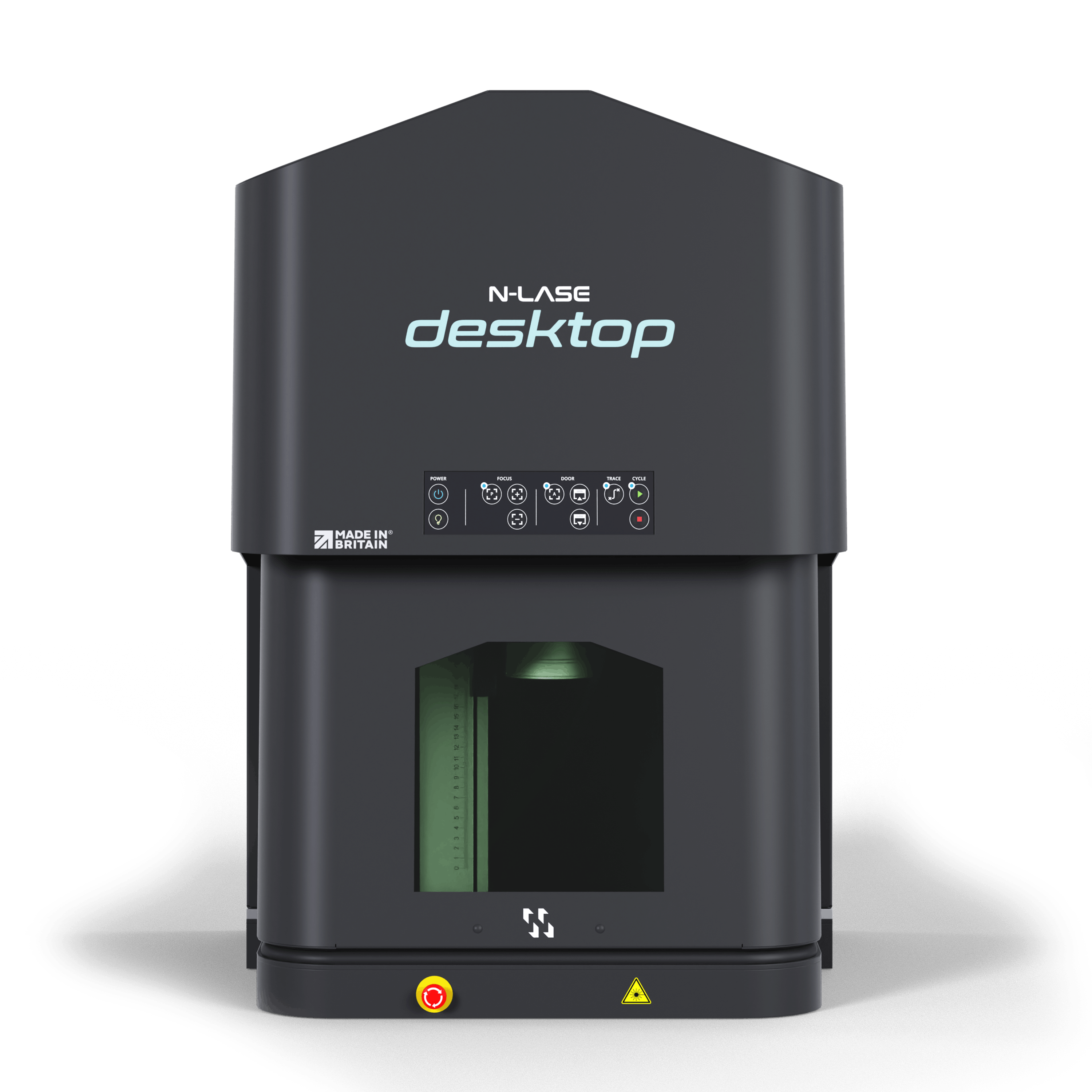

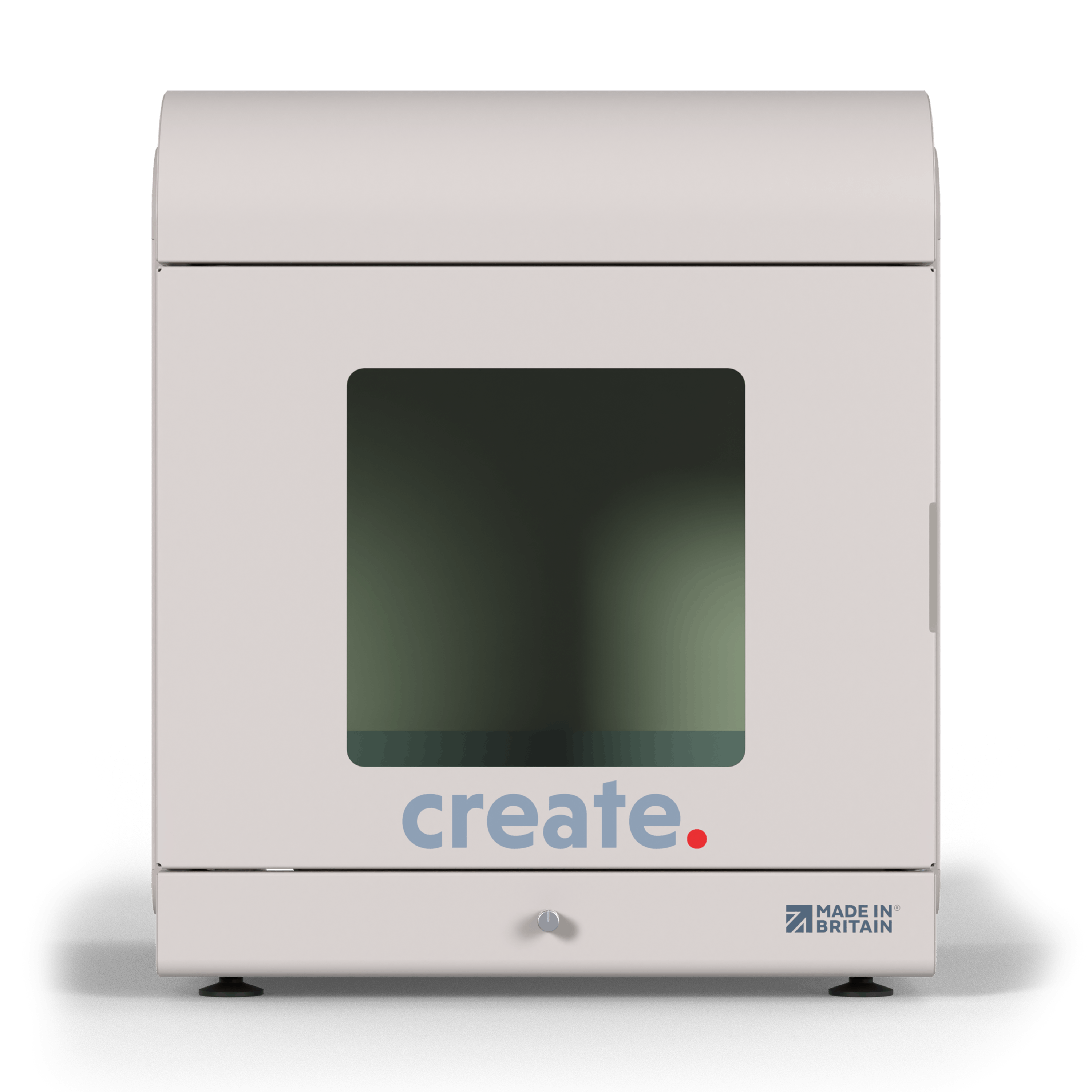

Laser engraving cast iron is most commonly achieved by annealing, a process where thelaser heats the surface of the metalto form an oxide layer. The colour change in laser annealing is caused by a chemical change in the surface of the metal, meaning that no material is vaporised or removed from the cast iron surface. Crack propagation is an especially significant concern for cast iron, and iron laser engraving is an excellent option for creating permanent marks on cast iron without compromising its physical integrity.