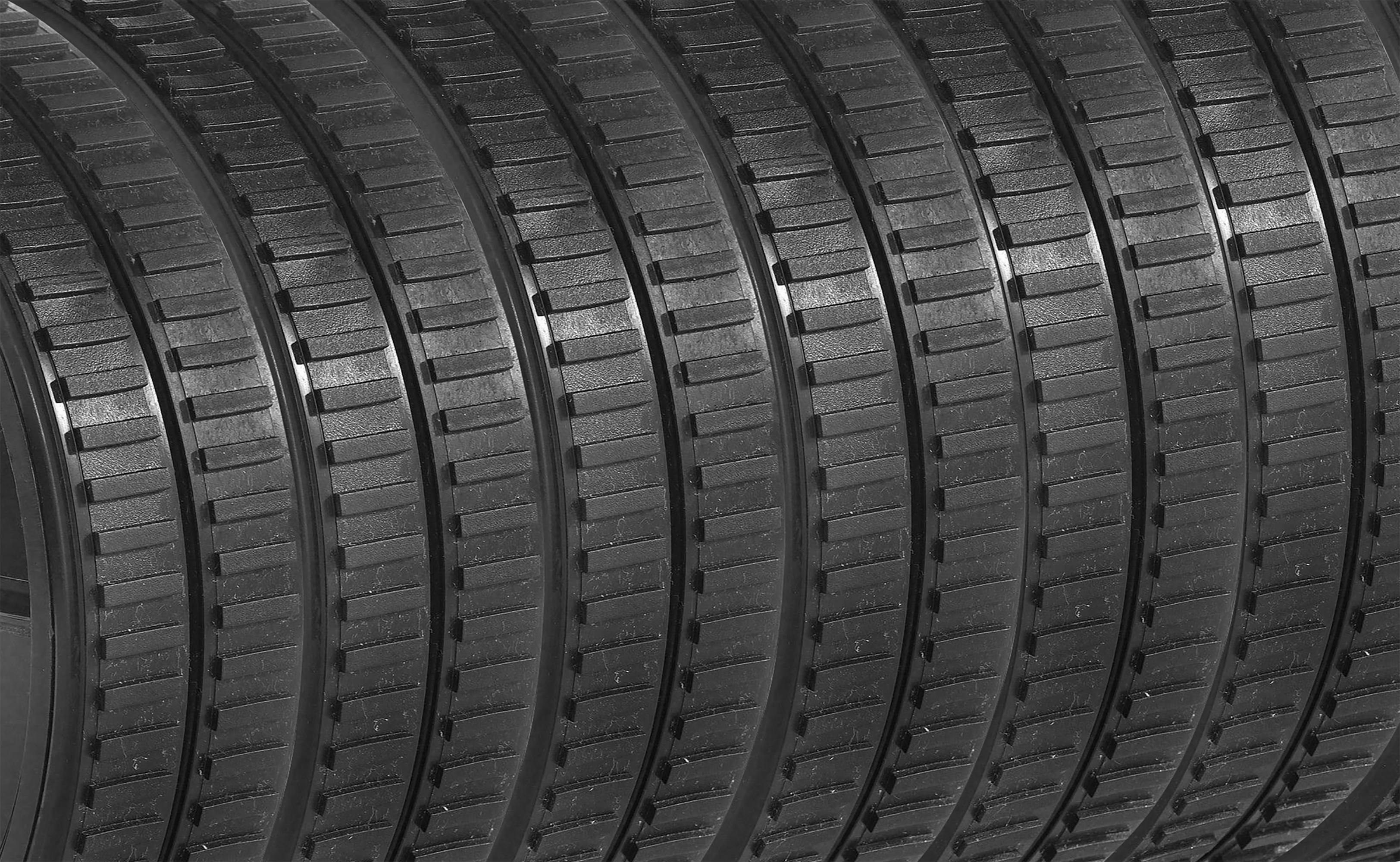

Rubber in Industrial Applications

Laser technologies have many applications in the rubber industry, including cutting, engraving, welding, and marking. Laser cutting is a precise and efficient method for creating intricate shapes and designs in rubber materials, such as gaskets and seals. Laser cutting allows for clean and accurate cuts, reducing waste and improving production efficiency. Laser cutting is also useful in the production of custom rubber parts and components, as it allows for the creation of unique shapes and sizes that cannot be achieved with traditional cutting methods.

Laser engraving is another application of laser technologies in the rubber industry. Laser engraving is a process that uses a laser beam to etch text, logos, and other markings onto the surface of rubber materials. This method produces a permanent and durable result, making it ideal for applications such as product branding and identification. Laser engraving is also useful for creating decorative designs on rubber products, such as phone cases and other accessories.

Laser welding is a third application of laser technologies in the rubber industry. Laser welding is a process that uses a laser beam to melt and join two pieces of rubber together. This method produces strong and reliable bonds that are resistant to wear and tear. Laser welding is useful for applications such as the manufacture of automotive components and medical devices, where a secure and durable seal is essential. Overall, laser technologies offer a versatile and efficient solution for many rubber-related applications.