Sterling Silver in Retail Applications

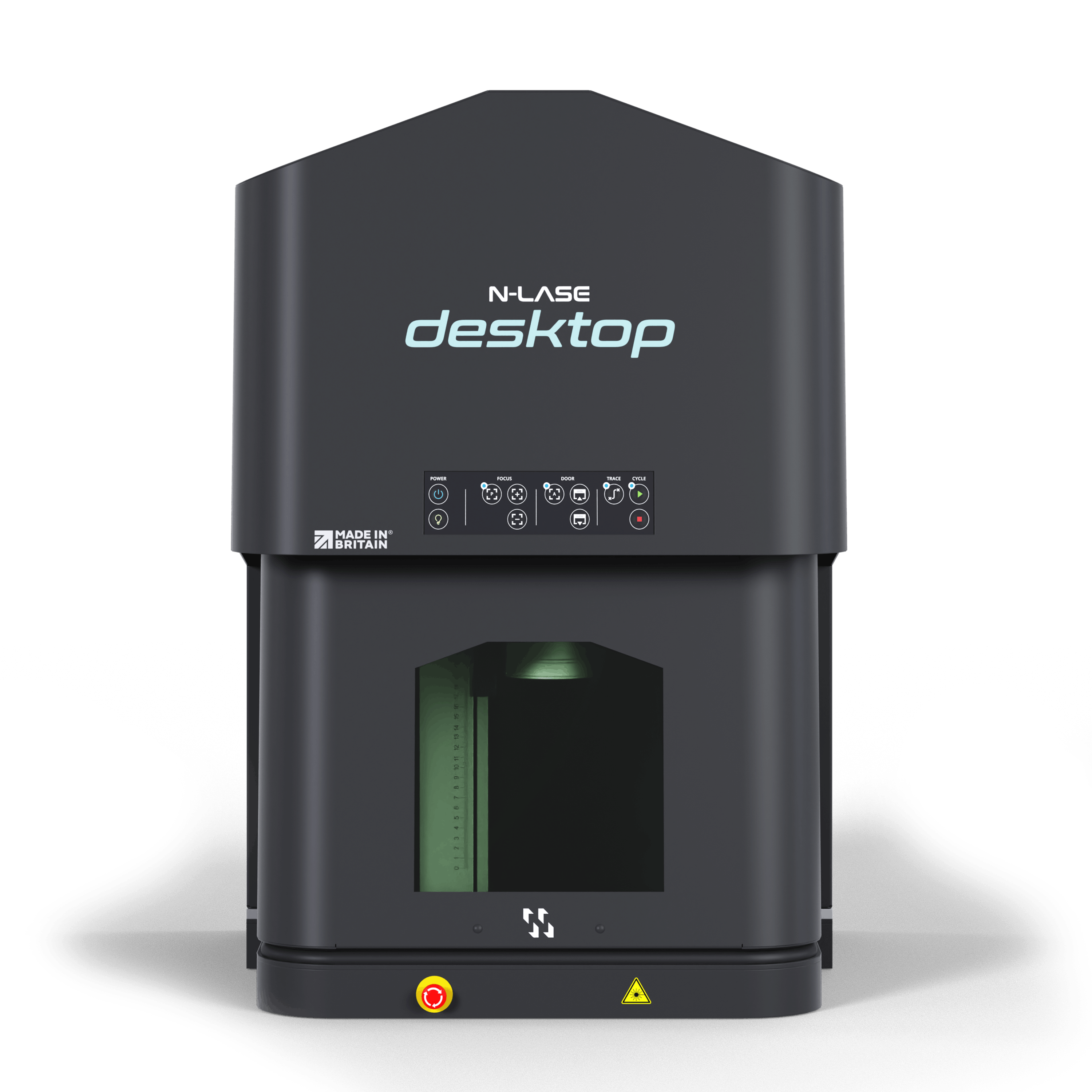

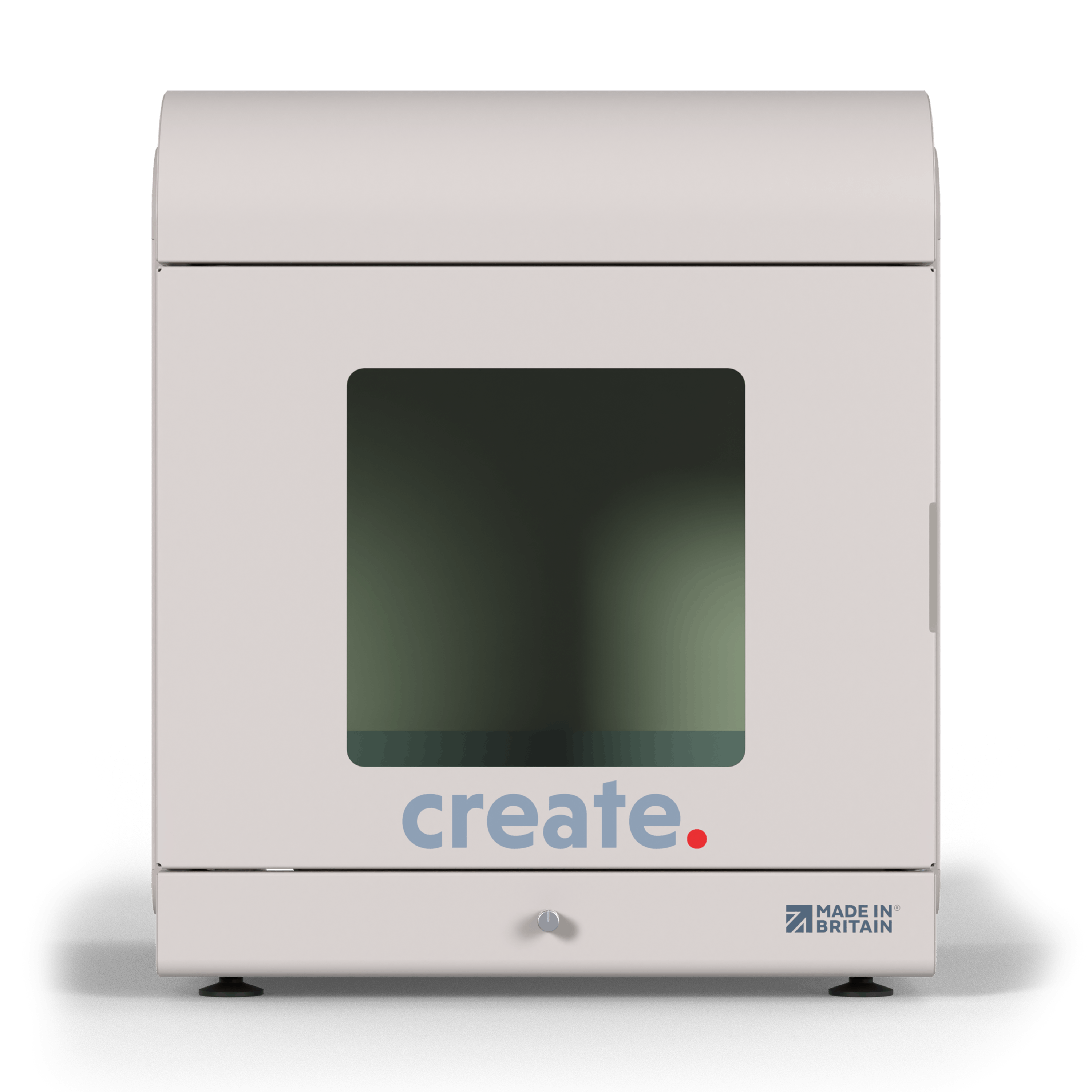

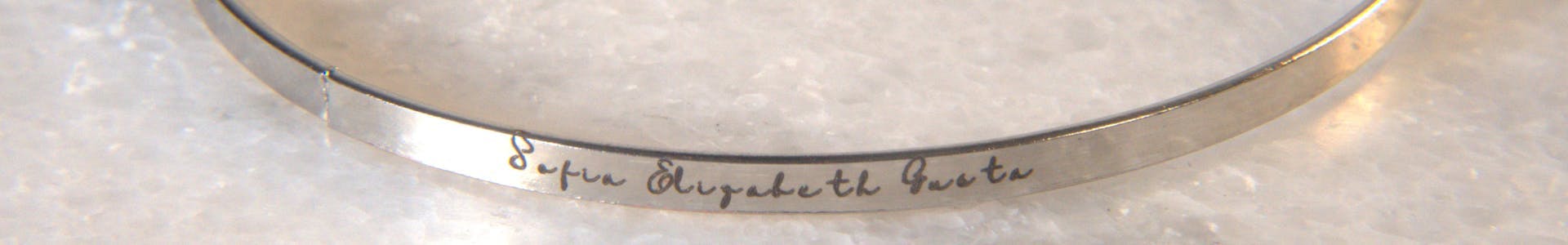

Laser engraving machines have become an indispensable tool for many businesses and manufacturing houses that work with this metal. It is easy to laser engrave etch or mark sterling silver in seconds! What’s more, the precision of the laser beam is so accurate that a human worker or craftsman would find difficult to match.

Increasingly, shoppers want to make age-old gifts and products more special by adding an individual’s name or personal message. Businesses that offer to personalise their products on the fly stand to win in a competitive marketplace. The laser machine is perfectly suited for such personalisation tasks. Simply open the software, edit the text and press start to begin the laser process.

A laser engraving machine is a perfect fit for engraving sterling silver. The precision of the laser beam ensures that very little is wasted when engraving or cutting the material. With the cost of the metal being so high, any wastage can affect a business’s bottom-line. Therefore, manufacturers are increasingly utilising the power of the laser to reduce wastage and increase productivity. When working with precious metals ,the standard process for etching, engraving, marking is known as “annealing”. The annealing process is achieved by changing the colour of the silver metal by oxidation without any material loss. Since sterling silver is a relatively soft metal, a successful mark requires high-speed and limited power. The advantage of using such parameters means that a mark can be completed in seconds.