Stainless Steel in Industrial Applications

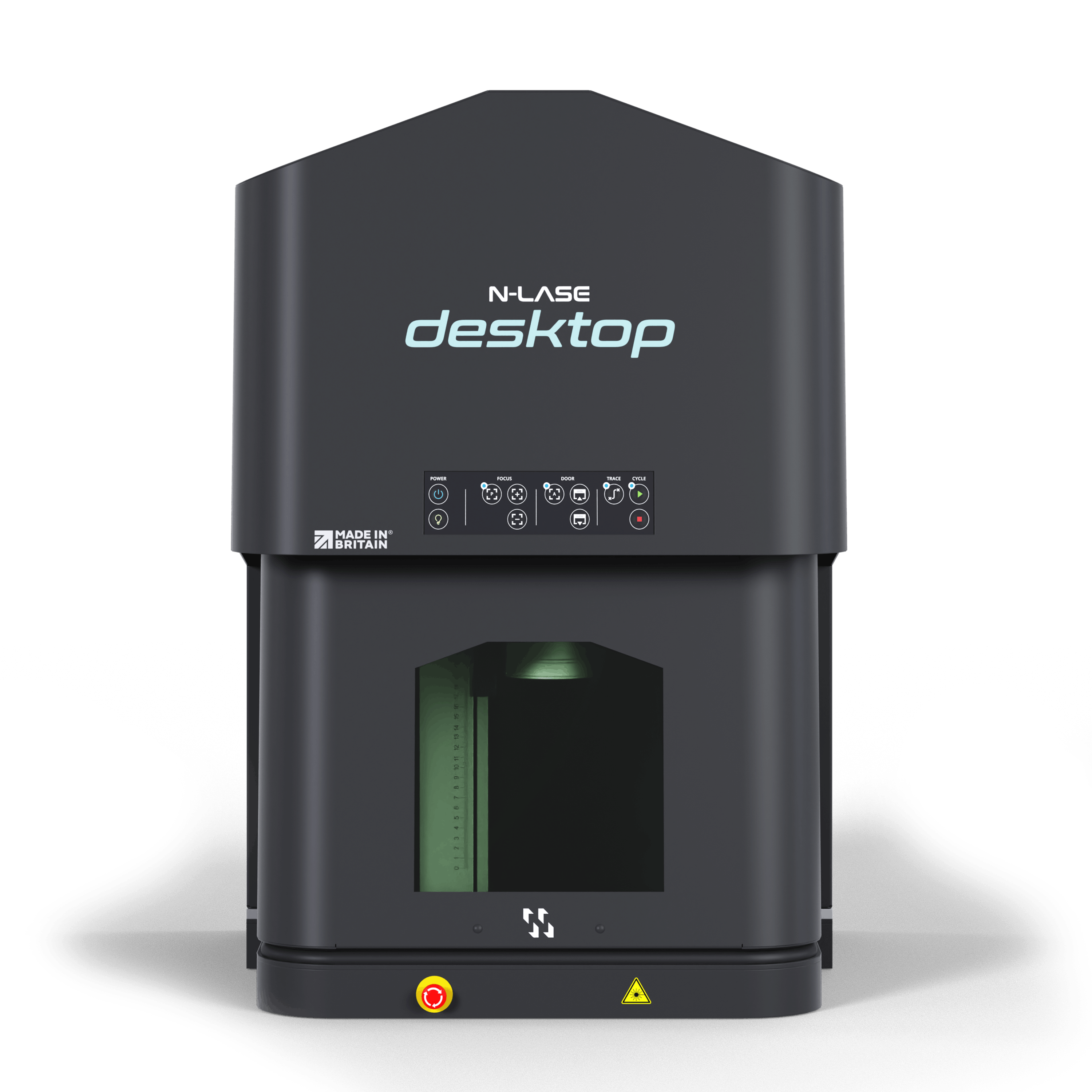

Fiber laser machines are the standard technology for metal engraving. Merely varying the wattage output of a fiber laser allows it to create different markings and engravings with varying depths. A fiber machine is also very accurate – with diameters as low as 0.1mm, fiber lasers can create incredibly detailed designs. Best of all, fiber machines do not require pre-treatment to etch stainless steel.

A fiber laser also finishes the same amount of work faster – the output of 2 or 3 CO2 machines can be reproduced by a single fiber laser system. In terms of electrical efficiency, fiber lasers are clearly the winner, using only about a third of the power to produce the same amount of work as a CO2 laser. Stainless steel is one of the most widely used metals across several industries. Prized primarily due to its corrosion resistance, stainless steel comes in different grades and variants according to the ratio of chromium and molybdenum mixed into the steel alloy material.

The medical industry is a particularly heavy user of stainless steel because of the industry’s strict requirement for materials that will not produce or transmit biological and chemical contaminants. Surgical tools made of this metal can withstand repeated cycles of sterilisation by autoclave and the oxidative effect of several sterilising chemicals. Stainless steel prosthetics, such as hip bone replacements and cranial plates, can be made of alloys especially designed to resist mechanical wear and biological reactions.

Lasers engraving technology of complies with the FDA’s mandate to mark all medical tools and devices with a unique device identifier (UDI). This requirement creates a system of traceability and liability for all medical devices, where each product can be traced and identified to its manufacturer. Having such a system compels medical device manufacturers to be accountable for the quality of their products in case of a product recall.

Medical devices, in particular, should not have deep etches, as these become perfect breeding grounds for bacteria. This makes annealing stainless steel the ideal appropriate process for marking, as it merely changing the colour of the metal through a chemical reaction without consuming any of the material. The surface of the material remains as smooth as it was before the engraving process.