A MOPA (Master Oscillator Power Amplifier) fiber laser engraving machine is an advanced type of laser engraver that utilises fiber laser technology along with a two-stage process for amplifying the laser signal.

In the first stage, the master oscillator generates a highly coherent laser signal with the desired pulse shape and length. This signal is then amplified by the power amplifier, which increases the power of the laser signal while maintaining its original characteristics.

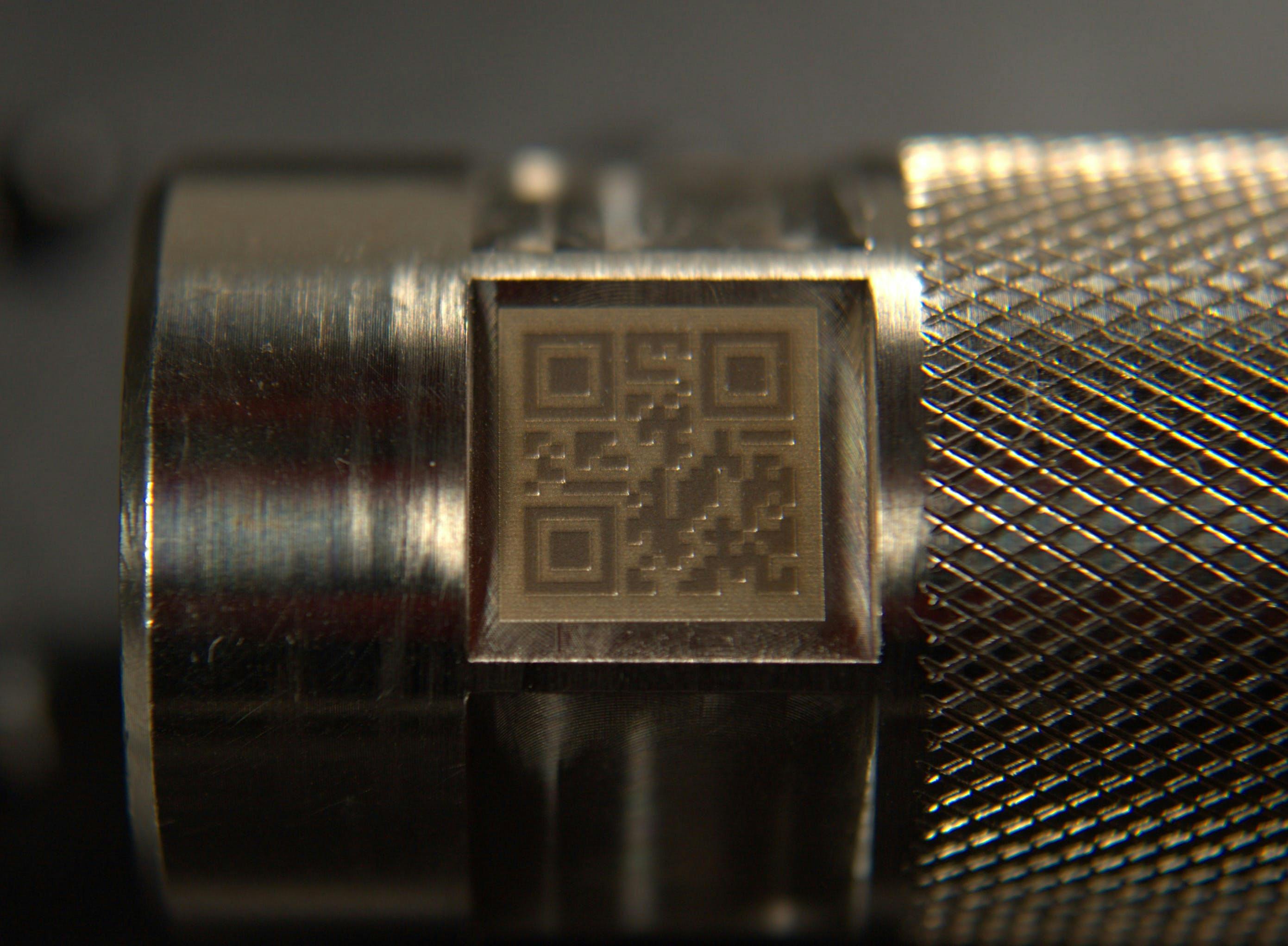

This technology enables precise control over the pulse width and frequency, which is crucial for a wide variety of applications, including engraving, marking, cutting, and welding.

MOPA fiber laser machines offer superior performance in terms of engraving quality and flexibility compared to traditional fiber laser engraving machines. They can be used to engrave a broad spectrum of materials, including sensitive ones, without causing thermal damage, thanks to their adjustable pulse durations. Moreover, they can create different colours on certain metals, such as stainless steel, by manipulating pulse durations and frequencies.

Due to this larger range in pulse duration, the scope of applications is larger for a MOPA laser. A MOPA laser can produce precise, high contrast engravings on the following materials:

However, it's important to note that the engraving quality and effects can vary based on the specific type of material and the settings used. Always run tests before processing large batches of material.

In a MOPA fiber laser system, the structure is divided into two distinct parts: the master oscillator and the power amplifier.

The master oscillator generates the initial laser signal. This signal has a low power level, but it's highly coherent and carries the desired pulse shape and duration. By adjusting the settings of the master oscillator, users can control the pulse shape and duration, having a direct influence over the laser's interaction with various materials.

Once the initial signal is generated, it's sent to the power amplifier, which dramatically increases the output power of the laser signal without affecting its original characteristics, like pulse shape and duration.

The ability to control pulse duration is particularly useful when engraving materials that react differently to heat, as it can minimise thermal damage and discolouration, leading to a better quality of engraving.

For example, shorter pulses can be used to achieve high contrast marking on plastics or to mark sensitive materials, whereas longer pulses can be useful for engraving certain types of metals or for applications like deep engraving or colour marking on stainless steel.

The MOPA marking machines offer several advantages over other types of laser technology. These include:

Each of these advantages makes the MOPA fiber laser engraving machine a versatile and valuable tool for businesses across a range of industries, from manufacturing and engineering to retail and creative.

These machines are designed for high-precision, high-speed engraving, which makes them ideal for industrial applications. Here are a few reasons why MOPA fiber lasers are well-suited to industrial-scale operations:

However, the suitability of a MOPA laser system for a specific industrial application also depends on the specific requirements of that application, such as the volume of items to be engraved, the type and thickness of the material, and the required depth of the engraving. Get in touch with our knowledgeable team to discuss your laser requirements and find the right machine for you.

Whether you're interested in finding out more about our lasers, joining our team or becoming a distributor - our team will be shortly in touch with you!