What Are The Benefits of Using Automotive Laser Marking?

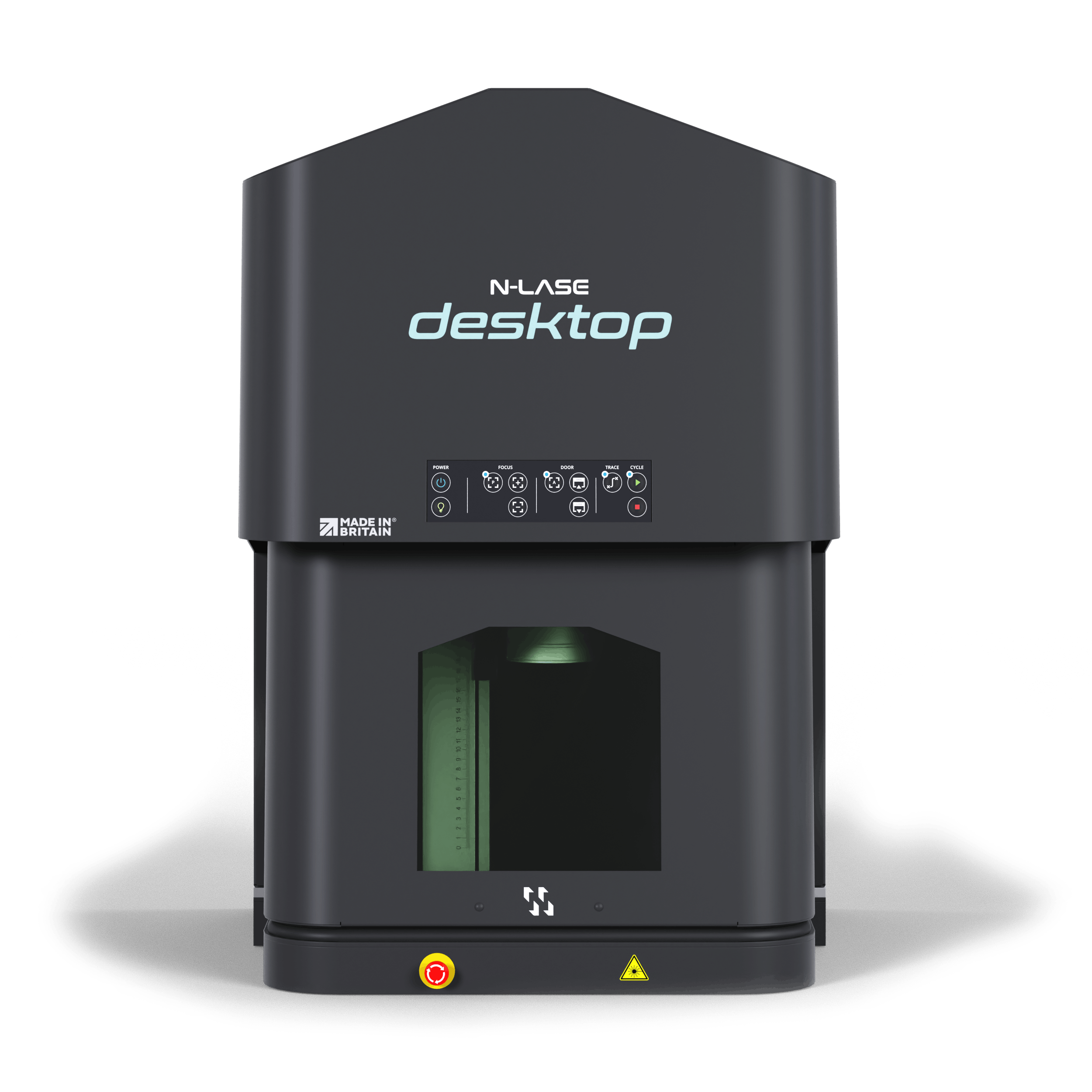

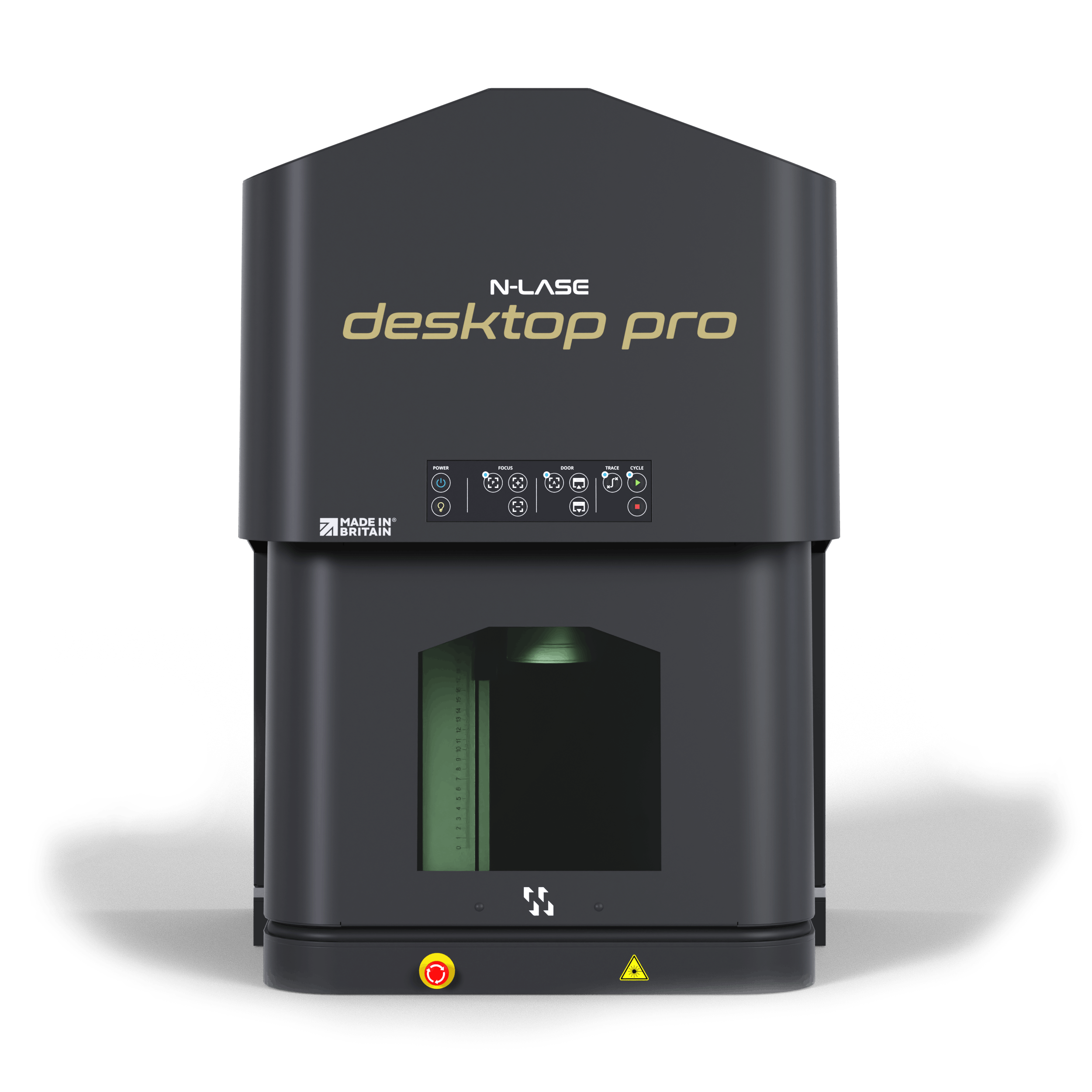

Automotive laser etching is a well-developed technology with various turnkey solutions, making it easy to integrate into any production line. Our laser marking system commonly comes bundled with its own software package that has been designed to be user-friendly.

The system can work with dynamic data to make progressive marks with minimal user intervention. Being almost entirely automated, laser marking systems are not labour-intensive and will free up technical operators to concentrate on the more involved steps of the manufacturing process. The low level of user intervention also means that laser engraving technology is highly accurate and reliable. Since laser marking systems have very few moving parts, their maintenance needs are also lower compared to other similar technologies.

Automotive laser marking provides high precision and accuracy, high contrast, permanence, and durability, making it ideal for producing permanent, high-quality markings on automotive parts. It is also faster, more flexible, and more cost effective than traditional marking methods such as mechanical engraving or chemical etching.

Non-Contact, Fast Technology

Laser engraving for automotive parts is the only non-contact technology used to mark equipment parts and traceability codes. This reduces wear and tear on the parts of the laser marking equipment - reducing repair and replacement parts. The contactless technology also reduces the chance of damage during the process, which can often be seen in more traditional part marking and methods such as dot-preen engraving.

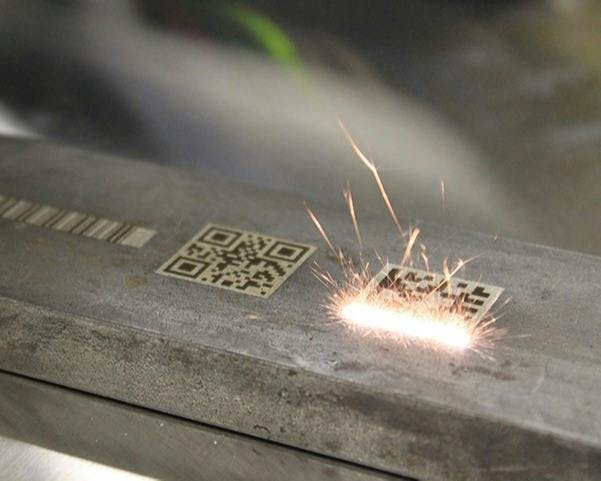

Laser marking technology is also incredibly fast. Even highly detailed designs, such as small barcodes or QR codes on printed circuit boards (PCBs), hardly take more than five seconds to finish.

Permanent and Cost-Effective

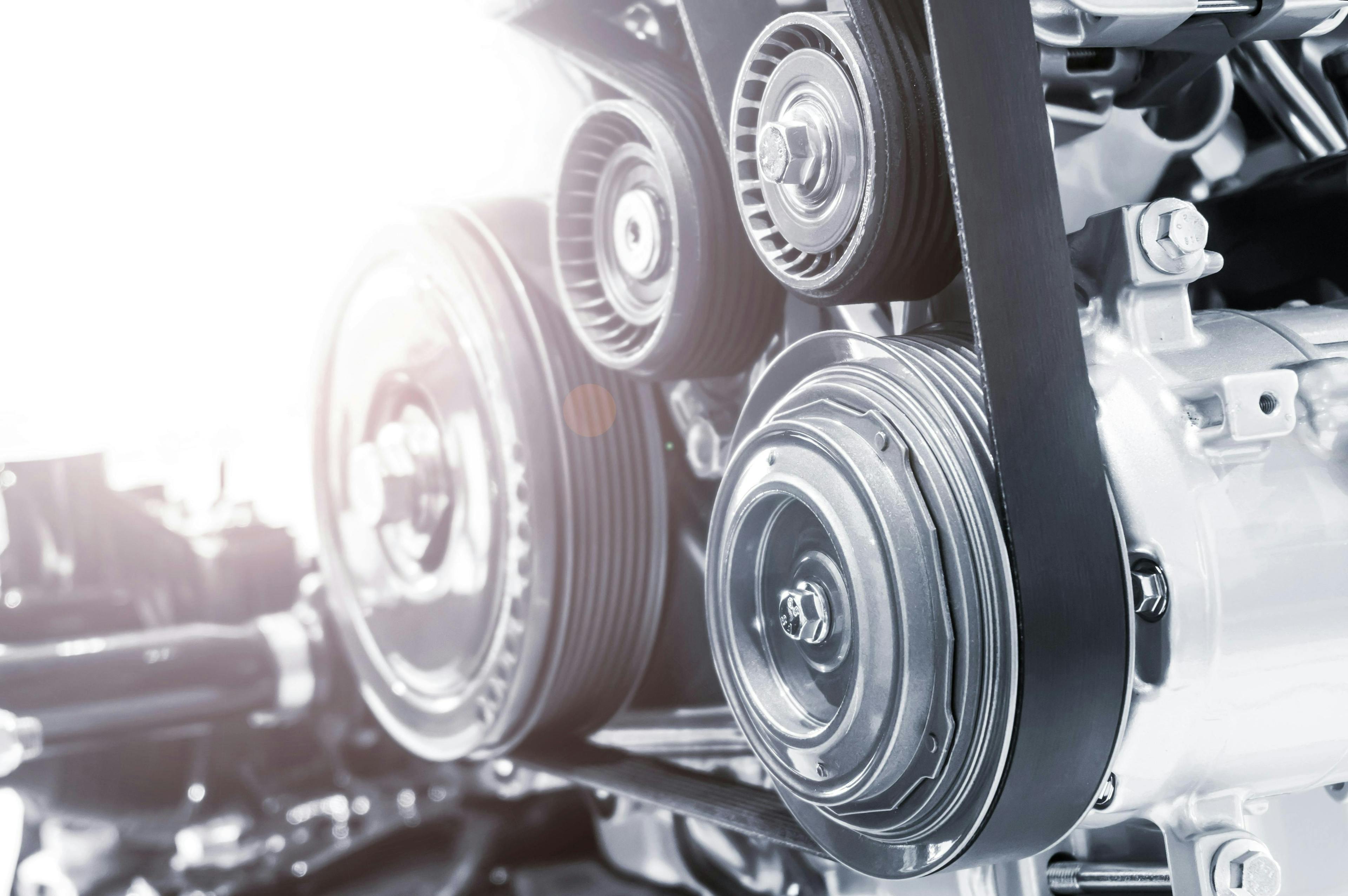

Laser engraving marks are precise and accurate, as well as legible and permanent. This is incredibly important in automotive parts that experience incredibly high temperatures and frictional forces - for example, individual components of the braking system or piston engine parts.

A brake rotor can heat up to a temperature of 900°F when brakes are engaged at high speed, making a part number that does not degrade with heat particularly important.

Compared to other methods of marking automotive parts, laser etching technology is much more cost-efficient. This is due to full automation and fewer moving parts, reducing the workforce required and part replacement costs.

Contactless laser technology also reduces the likelihood of production defects, as well as any need for costly waste disposal.